Vacuum-Compatible Adjusters

- 1/4"-100 Vented Adjusters for Vacuum Use

- Adjuster Lengths from 1/2" to 2"

- 0.01" Travel per Revolution

- All Adjusters are Shipped Double

Vacuum-Bagged

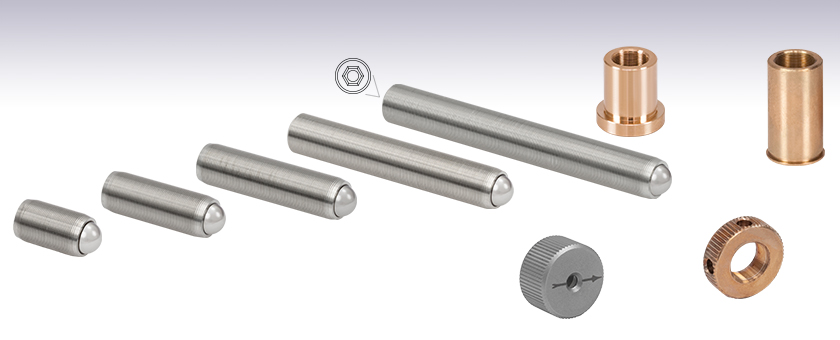

F25US075V

0.75" Long Vented

Hex Adjuster

F25US100V

1.00" Long Vented

Hex Adjuster

F25US200V

2.00" Long Vented

Hex Adjuster

F25US050V

0.50" Long Vented

Hex Adjuster

F25US150V

1.50" Long Vented

Hex Adjuster

LN25100

Lock Nut

F25USA1

Ø3/8" Barrel Adapter

F25USN1P

Ø0.34" Bushing

5/64" (2.0 mm)

Hex Socket, Vented

POLARIS-N5

Removable Adjuster Knob

Please Wait

Additional Vacuum-Compatible Components

Many of our other Optomechanical Components can be special ordered for vacuum use. Contact Tech Sales for details.

Features

- 100 TPI Fine Adjustment

- Adjusters Feature a 5/64" (2.0 mm) Hex Socket

- All Adjusters Usable at 10-6 Torr (Knobs Down to 10-5 Torr) Directly Out of the Packaging

- Compatible with Lower Pressures with Additional User Processing

- Removable Adjustment Knobs Allow for Adjustment without Hex Key

- Threaded Bushings, Lock Nuts, and Locking Collar for Adjuster Integration

- Barrel Adapter for Integration with Linear Translation Stages

Thorlabs offers vacuum-compatible versions of our 1/4"-100 adjusters which are fabricated from specially selected grades of stainless steel for vacuum and cleanroom use. They exceed class 3 standards and each screw is individually tested with a master gauge set that ensures the interoperability of our adjuster screws and threaded bushings. Adjusters are available in 0.50" increments from 0.50" up to 2.00" long and are packaged in double airtight bags for cleanroom and vacuum applications. A variety of 1/4"-100 threaded bushings, lock nuts, locking collars and barrel adapter are available to simplify the integration of fine adjusters in your application.

Vacuum Compatibility Information

Our vacuum-compatible adjusters and knobs are chemically cleaned and prepared for vacuum applications before packaging. Directly out of the packaging, they are compatible with vacuum environments down to 10-6 Torr or 10-5 Torr, respectively. With additional cleaning and processing, they can be used at even lower pressures, only limited by the outgassing rate of the stainless steel. The material properties of the stainless steel and the cleaning methods completed by the end user should be used to determine the appropriateness of these products and materials in a specific vacuum system.

We also offer other optomechanical components which may be used in vacuum applications. All of our Polaris® Mirror Mounts are vacuum compatible. We also offer Unanodized Aluminum or Passivated Stainless Steel Breadboards, which may be used in vacuum applications after undergoing cleaning and processing by the end user.

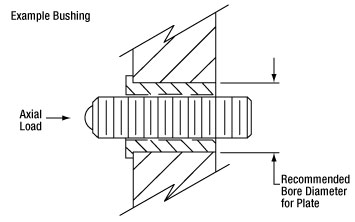

Integrating Fine Adjustment Screws Into Optomechanical Systems

The assembly process begins by producing the appropriately sized mating hole for the threaded bushing. The recommended bore diameters can be found with the product information for each bushing sold below. Given the close fit between the threaded bushing and the mating adjuster screw, we caution against using a press fit to assemble these products. For our own production needs, we use a permanent anaerobic adhesive that provides excellent long-term performance. Locking bushings with nuts do not require adhesive as they are held in place by the locking nut.

We recommend using EPO-TEK®* 353ND epoxy, Item # 353NDPK, or equivalent. In order to ensure maximum strength between the bonded parts, we strongly urge the user to carefully follow the instructions provided by EPO-TEK.

When assembling, apply a small amount of the EPO-TEK epoxy to the threaded bushing only. Rotate the bushing as it is installed to ensure a uniform distribution of the epoxy. After insertion, remove any excess epoxy from around the part and allow to properly cure per epoxy instructions.

As shown in the figure to the right, the flange on the mating bushing is designed to support the axial load of the screw and bushing assembly.

*EPO-TEK is a registered trademark of Epoxy Technology, Inc.

Drilling and Tapping

While we recommend using our fine adjusters with the appropriately matched threaded bushing (sold below), it is also possible to incorporate them directly into a part or material by creating a threaded hole. For the adjusters on this page, the diameter of the pilot bore should be 0.240" +0.002" / -0.001". The hole can then be tapped with a TAP14100 tap. For fine pitch threads, it is especially important to tightly tolerance the pilot bore because of the shallow thread depth. For more information, see our taps and drill bit kit page.

OEM & Custom Precision Screws

Thorlabs manufactures custom and high volume OEM precision screws and bushings with various diameters, lengths, and threads. To inquire about custom or OEM precision screws, please contact Technical Sales or use the "Contact Us" button. A specialist will contact you within 24 hours or the next business day.

Precision Screw Capabilities

Thorlabs' in-house machine shop, located in Newton, NJ, gives us the ability to quickly produce large quantities of precision screws and bushings. We are equipped to manufacture screw diameters ranging from 2 mm to 20 mm with lengths up to 165 mm and a maximum thread pitch of 200 TPI. Our standard adjuster screw design has a hardened steel ball tip to provide a single point of contact; for other applications we are able to provide adjusters without the steel ball. Custom orders can be achieved on a case-by-case basis. For large orders of an item, Thorlabs passes on to the customer the cost savings associated with planned production of high volumes of that item. For more information on Thorlabs' discount pricing policy, click the "V" link in the OEM & Custom Precision Screws box. We also offer a large variety of stock precision screws, which are available here.

Fast Turn-Around Times

Our experienced, highly skilled machinists are running our on-site Citizen Swiss Screw Machines 24 hours a day, allowing us to produce high-volume custom and OEM orders. Each machine is capable of running unattended, producing one screw every 30 to 120 seconds. This flexibility allows us to fulfill multiple orders at once without sacrificing quality.

High Quality

Thorlabs inspects all of our fabricated precision screws and bushings after the initial fabrication process and right before packaging. All inspections adhere to the ANSI AQL1.5 acceptable quality level, which states that if a certain percentage, based upon the amount of product in a certain lot, does not meet specification, then the entire lot is not sold. This ensures that all customers receive the highest quality product every time and that all items will be of equal performance.

Video 33A Precision Screw Production

| Posted Comments: | |

| No Comments Posted |

- Five Lengths Available from 0.50" to 2.00"

- 5/64" (2 mm) Hex Key Compatible

- Max Load: 15 lbs (6.8 kg)

- Usable Down to 10-6 Torr as Shipped

- Axially-Vented Ball Seat

- Uses Vacuum-Compatible Epoxy

Our high-precision 1/4"-100 Fine Hex Adjusters can be adjusted with a 5/64" (2 mm) hex key or a POLARIS-N5 removable knob (sold below). These vacuum-compatible adjusters have a maximum load of 15 lbs (6.8 kg). The adjuster body is constructed of 304L stainless steel. The axial vent hole allows for air trapped under the ball to escape, allowing these to be used down to 10-6 Torr as shipped. The 440 stainless steel ball tip is fixed onto the adjuster with vacuum-compatible 353NDPK epoxy.

Cleanroom and Vacuum Compatibility

These 1/4"-100 adjusters are compatible with cleanroom and vacuum applications. The adjusters are chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface. After passivation, it is double vacuum bagged to eliminate contamination when transported into a cleanroom.

Drilling and Tapping

While we recommend using our fine adjusters with the appropriately matched threaded bushing (sold below), it is also possible to incorporate them directly into a part or material by creating a threaded hole. For the adjusters on this page, the diameter of the pilot bore should be 0.240" +0.002" / -0.001". The hole can then be tapped with a TAP14100 tap. For fine pitch threads, it is especially important to tightly tolerance the pilot bore because of the shallow thread depth. For more information, see our taps and drill bit kit page.

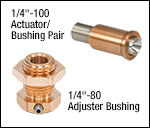

- Ideal for Slip Fit

- Two Lengths Available

- Material: 510 Phosphor Bronze (Vacuum Rated for 10-6 Torr)

- Recommended Bore Diameter: 0.3395" +0.0005"/-0.0000"

Our 1/4"-100 Threaded Bushings are commonly used in slip fit applications where fine adjusters are needed. Due to the tolerances of our fine adjusters, we discourage press fitting these bushings. The recommended bore diameter for our 1/4"-100 bushings is 0.3395" +0.0005"/-0.0000". To learn more about the use of fine adjustment screws and bushings in optomechanical systems, please see the Integration tab above.

- Material: 510 Phosphor Bronze (Vacuum Rated for 10-6 Torr)

- Adapts 1/4"-100 Adjusters to Ø3/8" Barrel Size

- Recommended Bore Diameter: 0.375" +0.002"/-0.000"

This 1/4"-100 threaded to Ø3/8" barrel adapter is made from 510 Phosphor Bronze (vacuum rated for 10-6 torr). This item allows our 1/4"-100 adjusters to be used with linear translation stages that accept actuators with Ø3/8" (Ø9.5 mm) barrels. The photo to the right shows an adjuster screw used as a replacement for the actuator included with the translation stage. For vacuum applications, we recommend a thorough ultrasonic cleaning to remove any grease or particulates prior to use.

- Knurled Outside Diameter for Easy Tightening

- Material: 510 Phosphor Bronze

- Vacuum Compatibility: 10-6 Torr

The LN25100 lock nut features a knurled outside diameter, which helps when tightening or loosening the nut. This lock nut is made from 510 Phosphor Bronze, which is vacuum rated for 10-6 Torr. Each nut features blind holes that allow a hex key to be used to help tighten the lock nut.

- Lock Nut Compatible with the 1/4"-100 Adjusters Sold Above

- Also Compatible with the Adjusters Included on our Polaris Mounts for Ø1" Optics

- Tighten Using a 13 mm Hex Thin-Head or Cone Wrench

- 0.08" (1.9 mm) Thick

The POLARIS-LN1 stainless steel lock nut can be used with any 1/4"-100 adjuster for long-term stability and features a 13 mm hex. This lock nut is compatible with Polaris mounts that have 1/4"-100 adjusters, excluding the piezo-driven mounts, mounts with low-profile adjusters, and vertically driven mounts. The adjuster can be held in place with an adjuster thumbscrew or hex key while lightly tightening the lock nut by hand or with a 13 mm thin-head wrench or cone wrench.

For applications that require frequent tuning of the adjusters, the lock nuts only need to be lightly tightened by hand to a torque of approximately 4 to 8 oz-in (0.03 to 0.06 N·m). For long term stability, we recommend tightening to a torque of 32 oz-in, which can be achieved by using our TW13 preset torque wrench. To avoid cross threading the lock nut, place it against the adjuster and "unscrew" the lock nut until you feel a slight drop; then thread the lock nut onto the adjuster.

Cleanroom and Vacuum Compatibility

This lock nut is compatible with cleanroom and vacuum applications. The lock nut is chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface. After passivation, it is double vacuum bagged to eliminate contamination when transported into a cleanroom.

- Compact Locking Collar: Ø0.33" (Ø8.4 mm), 0.08" (1.9 mm) Thick

- Use One Collar To Lock an Adjuster to a Bushing

- Use Two Collars to Create a Hard Stop on an Adjuster

- Install and Remove with the POLARIS-T2 Spanner Wrench

The POLARIS-LNS1 locking collar is a compact alternative to the lock nut sold above. This locking collar is compatible with all of the 1/4"-100 adjusters sold on this page, as well as those used in many of our mirror mounts and stages. This locking collar is compatible with Polaris mounts that have 1/4"-100 adjusters, excluding the piezo-driven mounts and mounts with low-profile adjusters. Each collar is only 0.08" (1.9 mm) thick and constructed of stainless steel. We recommend the POLARIS-T2 Spanner Wrench to install or remove these locking collars. A center through hole allows a 2 mm ball driver to pass through the spanner wrench, so that the adjuster can be held in position while the locking collar is engaged.

The locking collar can be used to lock an adjuster in a desired position or to create a hard stop at any position to prevent overdriving an adjuster. For applications that require frequent tuning of the adjusters, the locking collar only needs to be lightly tightened to a torque of approximately 4 to 8 oz-in (0.03 to 0.06 N·m). For long term stability, we recommend tightening to a torque of 32 oz-in, which can be achieved by using our TW13 preset torque wrench in combination with the POLARIS-T2 wrench. To avoid cross threading the locking collar, place it against the adjuster and "unscrew" the collar until you feel a slight drop; then thread the collar onto the adjuster.

Cleanroom and Vacuum Compatibility

This locking collar is compatible with cleanroom and vacuum applications. The locking collar is chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface. After passivation, it is double vacuum bagged to eliminate contamination when transported into a cleanroom.

Click to Enlarge

POLARIS-K1C4 Mount with Optic and Optional POLARIS-N5 Removable Knobs Mounted to its 1/4"-100 Adjusters

- For Convenient Adjustment of 1/4"-100 Adjusters

- Attaches Directly to Adjuster Threading

- Sold Individually

The Polaris® Removable Knob for 1/4"-100 Adjusters allows the user to turn 1/4"-100 adjusters by hand. The knob threads directly onto an adjuster and maintains access to the adjuster screw's 5/64" (2 mm) hex socket via a Ø0.10" (2.5 mm) thru hole. The knobs are made from chemically cleaned and heat-treated 303 stainless steel that provides vacuum compatibility down to 10-9 Torr at 25 °C with proper bake out (10-5 Torr at 25 °C without bake out).

Cleanroom and Vacuum Compatibility

This removable knob is compatible with cleanroom and vacuum applications. The knob is chemically cleaned using the Carpenter AAA passivation method to remove sulfur, iron, and contaminants from the surface. After passivation, it is double vacuum bagged to eliminate contamination when transported into a cleanroom.

Products Home

Products Home

Zoom

Zoom

Vacuum-Compatible Adjusters

Vacuum-Compatible Adjusters