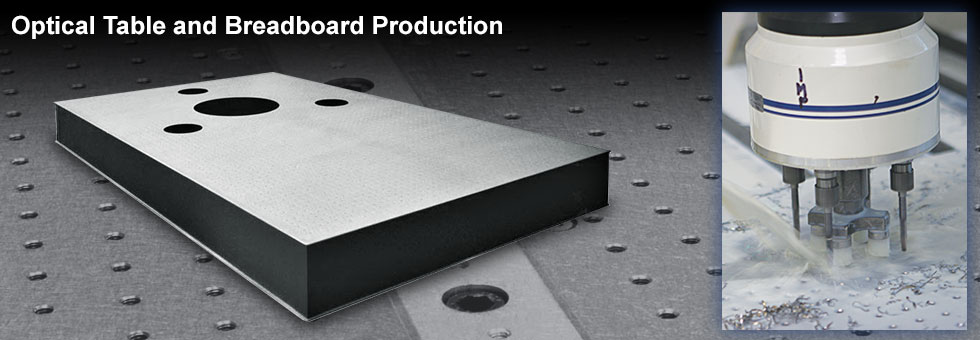

Tables and Breadboards Capabilities

Please Wait

Our team of experts is dedicated to creating high-quality

custom and standard optical tables and accessories.

Click to Enlarge

A machinist producing components for an optical table in

our Ely, United Kingdom production facility.

Tables, Breadboards, and Vibration Isolation Design and Manufacturing Processes

Thorlabs has facilities dedicated to the development and manufacture of optical tables, breadboards, and vibration isolation products. We also offer extensive custom capabilities. For an overview of our table manufacturing process see the video to the right, and for more details about each step in the process see the tabs above.

Key Capabilities

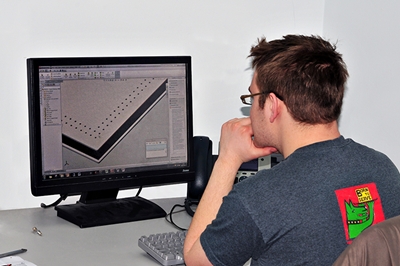

- Experienced In-House Design Engineers Producing Finite Detailed Solid Models and Production Drawings

- Custom Design Capabilities for Unique Table and Breadboard Solutions

Our team has over 25 years of experience, offering in-house design capabilities for tables, breadboards, vibration isolation products, and associated accessories. Thorlabs' optical tables and honeycomb breadboards must meet two basic design goals: the natural resonances of the table should be as high as possible (well above the frequency of ambient environmental vibrations) and the table should be well damped (to quickly damp vibrations caused by equipment on the surface). To meet these goals, our engineers use a variety of tools to refine their designs; for example, finite element analysis (FEA) allows our engineers to evaluate various materials and to identify possible unwanted material stresses. SolidWorks is employed to build 3D models of every design.

In addition to our stocked items, our engineers are capable of designing custom solutions for some of the most demanding and complex applications.

Key Capabilities

- Broad Range of Manufacturing Skills and Capabilities to Support Customers' Needs

- In-House Welding and Fabrication

- Dedicated Tables Manufacturing Production Facilities Producing Repeatable and Consistent Products

- Lean Manufacturing:

- Cross-Training Allows Staff to Meet Production Demands

- Use of Technology Leads to Increased Quality

- Efficient Organization Leads to Time Savings

Our production team's overall goal is to utilize the latest technologies and quality materials to enable us to rapidly produce consistent best-in-class products. We have made extensive investments in a broad range of dedicated plant and processes including large-bed CNC mills, multi-point tooling systems, laminating presses, automated trasfer systems, and fine finishing machines.

Our highly skilled production teams work in dedicated, resourced cells for machining, prepping, construction, and finishing. Cross-training empowers our adaptable production personnel. This in turn allows them to float between different cells flexing our output as production needs dictate. We operate a three-shift system to achieve production 24 hours a day.

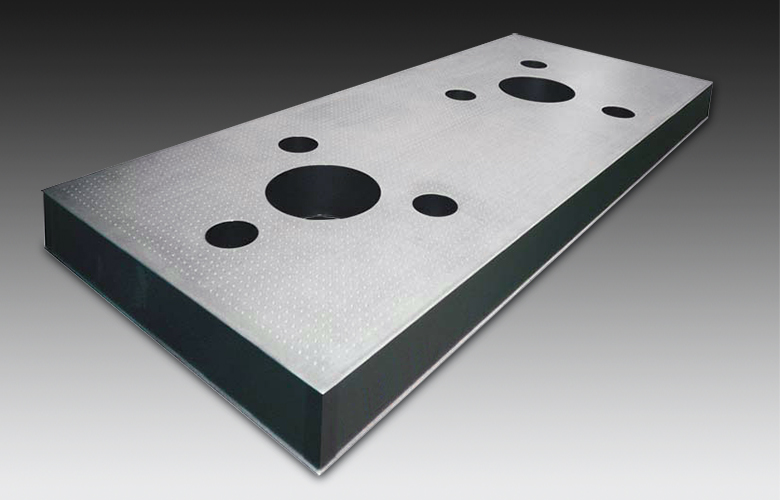

Tables and Breadboards Manufacturing Process

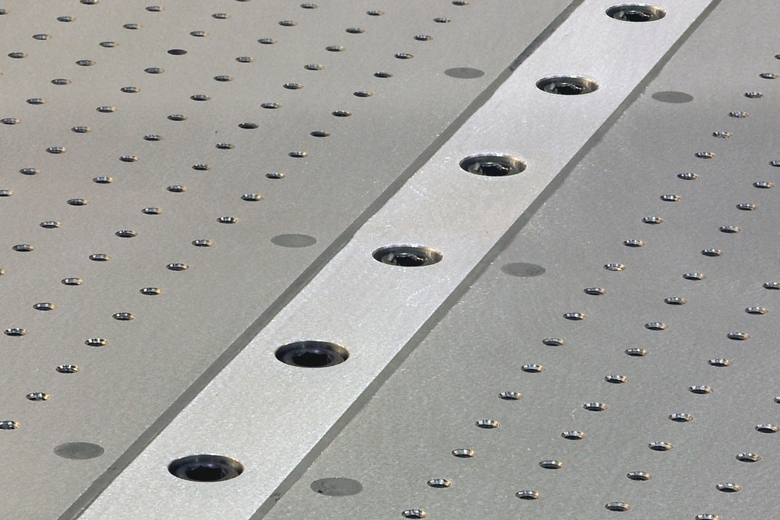

Thorlabs' optical tables and breadboards are the result of over 25 years of experience and and our goal to supply a single high-end grade of optical table for all photonics, imaging, and microscopy applications. The design is an XYZ symmetrical, isotropic construction. Thermal stability is maximized by using only steel or aluminum components (no wood or plastic materials). The core is symmetrically formed from strips of precision-crimped steel using accurate pressing tools and a high-tensile-strength epoxy adhesive. Geometric pitch is retained by using welded flat shims. The result is are manufactured of a composite of materials: steel or aluminum plates separated by an interior steel honeycomb structure. The honeycomb structure is designed to maximize stiffness, while the plates provide a stiff, flat working surface. Our honeycomb structure is fabricated from strips of precision-crimped steel, which are then bonded together with a high-tensile-strength epoxy adhesive. To further reduce vibrations originating on the tabletop, the table core contains dampers made from specially shaped pieces of inhomogeneous material. The top and bottom plates are bonded to the honeycomb using a hot pressing method and a modified structural epoxy adhesive. The adhesive is then cured under vacuum for 18 hours. This results in a bond between the various pieces of the composite structure that has a high tensile strength as well as an extremely high shear and peel strengths. The resulting tables and breadboards provide a stable work surface ideal for the most demanding applications. Each table is individually tested before it leaves the factory, and a unique test data certificate is incuded with each table.

Key Capabilities

- Laser Measurement Systems

- Vibration Transmissibility and Compliance Testing

All of our volume production designs are subject to extensive testing to ensure that they meet defined key function specifications. These include flatness, surface finish, reflectivity, transmissibility of isolation control systems, and compliance testing of breadboards, tabletops, and support structures. Compliance testing is performed by using an impulse hammer to apply a measured force to the top surface of the table or breadboard. Transducers attached to the surface detect the resultant vibrations. The signals from the transducers are interpreted by a PC running SignalCalc, and a frequency response spectrum (also known as a compliance curve) is produced.

Key Capabilities

- Customized Broadband Damped Tuning Available

- Large, Multiple-Table Joined Systems

- Custom Shapes and Finishes

- Cleanroom Compatible Options

- OEM Capabilities

- Dedicated Staff for Processing Quotes, Determining Pricing, and Producing Manufacturing Drawings

Our in-house production teams are uniquely qualified to handle special requests for modifications to our catalog products. Tables can be provided with special plates that allow two or more units to be securely coupled together into a single monolithic structure. We can also tailor the shape and size to suit your specific requirements. Special lengths and thicknesses can be manufactured, with or without access holes and cutouts for beam steering or cable routing. Custom finishes, non-standard materials (e.g., aluminum or virtually non-magnetic stainless steel), and customized damping solutions can also be provided.

To submit a quote request for a custom optical table or breaboard, please use our Custom Table and Breadboard Request Form.

| Posted Comments: | |

user

(posted 2023-01-08 18:53:17.857) There is a typo in the Japanese page, "設計" tab:

> そしてもう1つは乞うk学テーブルの振動を十分に減衰させること

「乞うk学」should be 「光学」. DCroxford

(posted 2023-01-10 05:32:43.0) Thank you for bringing this to our attention. A representative in your local office has been notified and will look into this. Oren Berger

(posted 2022-10-04 21:43:05.437) Hello,

I just recieved an optical table that i have purchased from you.

The surface is very dirty. When i sweep my hand on it my hand remains with a silvery looking residue like a silver paint.

First of all i hope it does not have any health issues for my staff. Is it?

Second, do you have a standard proceedure to clean this residue?

Exactly which materials can be used to clean the stainless steal breadboard without damaging it?

Which cloth to use?

Do you have this kind of cleaning materials and cloths that you can send me?

I will order soon more optical tables. How can i make sure that next time the tables will be clean?

Regards,

Oren cwright

(posted 2022-10-05 06:09:50.0) Response from Charles at Thorlabs: Thank you for your query. We are sorry to hear that your table arrived in this state. This could be from our finishing processes and is normally removed during processing. Unfortunately it appears you have received an outlier. We will reach out to you about this and how it can be cleaned. |

Products Home

Products Home

Table and Breadboard Manufacturing

Table and Breadboard Manufacturing