Optomechanics Capabilities

Please Wait

Optomechanics Capabilities

Thorlabs employs a variety of vertical design and manufacturing capabilities to produce its diverse catalog. These capabilities are also utilized to serve our customers' R&D and OEM customization needs. Our projects range from one-off product modifications to existing components to large-scale, custom OEM jobs. This page will outline key reasons our customers have chosen to work with us for optomechanical components and solutions. Contact us today to determine how Thorlabs can best assist with your next project.

- Flexible and Easy to Work With

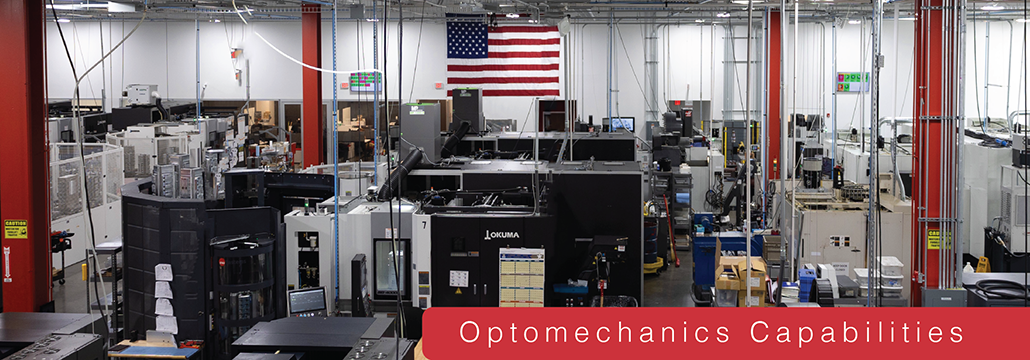

- Extensive In-House Manufacturing Operations in Newton, New Jersey

- Commitment to Quality and Compliance

- On-Time Delivery

- Custom Metrology and Testing

- Diverse Manufacturing Capabilities

- Resources to Scale Production

- Global Design and Solutions Experience

- ISO 9001:2015 and ITAR Certified

Optomechanics Design and Manufacturing Process

Design

From a kinematic mount to a multimodality imaging system, Thorlabs' adept mechanical engineering team has the talent and capabilities to deliver a final product tailored to your exact specifications and stringent application requirements. Our extensive design library contains tens of thousands of proven solutions developed to address the demanding requirements of photonics applications. In addition, we have access to engineering teams with expertise in nearly every engineering field in the industry. Our design teams are co-located with manufacturing so they can collaborate to ensure products meet customer expectations in terms of features, functionality, and manufacturing reliability – all while adhering to budget. This synergy between design and manufacturing not only propels our investments in manufacturing capabilities but also fuels continuous innovation in our designs, ensuring that we remain at the forefront of technological advancement.

Prototyping

In-house prototyping enables our engineers to rapidly iterate through design concepts providing valuable insights to our manufacturing team regarding any potential challenges. Leveraging additive manufacturing techniques, our engineers produce semi-functional components in the early stages of design refinement. As the design progresses, engineers collaborate directly with our machinists to ensure production-quality prototypes as quickly as the next day. Equipped with three- and five-axis CNC mills, CNC turning machines, and access to diverse manufacturing capabilities—such as wire electrical discharge machining (EDM) – our dedicated prototyping facility facilitates agile innovation and precision engineering.

Testing

With design and manufacturing for optomechanics, optics, fiber, and electronics all co-located in Newton, NJ, our design team has access to a variety of standard and unique metrology equipment that can measure dimensions, surfaces, and optical flatness. All designs are subject to extensive testing to ensure the product meets customer specifications. Different tests are performed throughout the manufacturing process to ensure both the machined components and final design perform as expected. This may be as simple as the use of "GO/NO GO" gauges for our thread adapters, or more advanced, such as the extensive thermal and repeatability testing performed on our Polaris® Mirror Mounts.

Production

The Thorlabs machine shop is a modern, high-performance facility that manufactures machined components for our optomechanics portfolio, existing OEM customers, and other Thorlabs groups. We have developed high-capacity production capabilities in horizontal milling, 5-axis milling, turning, and Swiss screw machining to support specific product lines, such as our Quick-Connect Stages. We have a wide variety of in-house capabilities, including wire EDM, CNC grinding, and CNC polishing. The Thorlabs machine shop has invested in Industry 4.0 sensing and data capabilities as well as automated production and inspection processes.

Assembly

Our assemblers make up a multidisciplinary team that produces Thorlabs’ standard optomechanical products as well as our customers' specialized requests. The team generates around 10,000 different builds per year with quantities ranging from one to tens of thousands. We utilize lean manufacturing concepts to maximize productivity and run a robust training program for all assemblers to ensure they possess the skills and experience to guarantee a high-quality product. Our 3 000 ft2 class 10 000 clean room is home to our Polaris® Mirror Mounts assembly as well as other products and specials that are intended for use in vacuum or other high-precision applications where dust or volatile organic compounds must be mitigated.

Specials and Custom Orders

Custom design and manufacturing have been part of Thorlabs’ optomechanics core capabilities from the start. In the beginning, this frequently involved making a small modification to a standard component so that a graduate student could realize their unique experimental setup. As the photonics industry has matured, so has our ability to customize designs and scale our production capacity and capabilities.

Some of our more popular categories of customized products include the Polaris® product line, fine adjusters and bushings, optical rails, lens tubes, optical cage components, manual stages, and multi-axis optical mounts.

Optomechanics Services

Flexible and Easy to Work With

At Thorlabs, we recognize the value of our customers' time. That’s why our webpages are crafted to streamline and facilitate your ordering experience. We prioritize ensuring key specifications and features are prominently displayed, alongside transparent shipping times and pricing. Our product imagery provides an accurate representation, reflecting our commitment to authenticity. Behind the scenes, our customer service, technical support, engineering, and sales teams collaborate to ensure every customer seeking a customized product or service experiences a timely, cost-effective, and transparent process.

Our Commitment to You

When starting a project with Thorlabs, we fully grasp that your success hinges on the timely delivery and seamless integration of the final product into your application. Through meticulous project planning, expert technical resources, and a dedicated point of contact for the duration of the project, our commitment is to ensure that your journey with us is both efficient and successful. We'll work closely with you to fully understand your application needs and provide seamless design-to-delivery service.

On-Time Delivery

The success of our customers is embodied in Thorlabs' objectives, promises, and brand. Recognizing the importance of on-time delivery to achieving customer success, we track our performance within our ERP system for each purchase and production order. By measuring on-time delivery at every step, Thorlabs continually refines and improves our operational processes so that our customers can rely on us as part of their supply chain or part of their new project timeline. Additionally, our global warehousing capabilities and utilization of kanban stocking methodology enable us to efficiently manage inventory for our OEM customers, further enhancing our commitment to seamless and reliable service.

Quality and Compliance

Thorlabs is an ISO 9001 certified company with continual certification since 2007. Our nonconformance procedures capture quality issues at their source, allow us to identify the root cause, and implement corrective action to prevent future occurrences of that issue, minimizing unexpected setbacks in our manufacturing processes. Photonics is a high-tech industry subject to an increasing number of regulations based on application and region. Our global team of compliance experts enable Thorlabs to seamlessly navigate these compliance requirements for our customers.

Our handheld CMM allows for portability on the machine shop floor. It can test accuracy without fully removing the observed part from the machine.

Metrology and Manufacturing

The scale and diversity of Thorlabs' product portfolio allow us to invest in a comprehensive suite of metrology equipment essential for both the development and manufacturing. Our optomechanical design and manufacturing teams leverage diverse technologies to ensure the dimensional accuracy and quality of motion of our optomechanical offerings. Moreover, they have access to the optical inspection equipment needed to measure the performance of the component when used in an application. Tailored to the specific product, our testing capabilities encompass a wide spectrum, including assessments for environmental durability, vibration resistance, lifetime expectancy, thermal performance, damage threshold, and more. This comprehensive approach ensures all products undergo rigorous evaluation to meet the highest standards of quality and reliability. Some of the key metrology resources for our optomechanical group include:

- Touch Probe CMM

- Touch probe CMM machines are instruments for checking dimensions on a wide range of machined parts. They can be programmed for use in continuous monitoring of manufactured parts and used on-the-fly to inspect a first-piece prototype. They also support a range of inspection needs for measuring dimensions in precision subassembly.

- Vision Systems

- Vision systems have evolved rapidly in the last decade and are now used to perform many inspection processes. Once programed, they can measure dimensional tolerances to nearly the same precision as a CMM in a fraction of the time. They are used to easily inspect and sort components, validate engraving, and, with some systems, evaluate surface quality and wear.

- Interferometer

- Many of the products and components in the photonics industry must be tested at the micrometer and nanometer level. For these inspection processes, we frequently use specialized interferometric instruments. For example, when we measure the performance of a linear stage, we use an interferometer to examine the pitch and roll deviation from perfect motion over the stage's range of travel. For a mount that holds an optic, an interferometer ensures that the mount is maintaining the surface flatness of the optic, or in some cases, is not creating stress induced birefringence.

- Gauges, Surface Plates, Hand Tools

- Gauges, surface plates, calipers, dial gauges, and other tools continue to play an important role in the precision manufacturing of photonics components. All of our metrology equipment is meticulously maintained, and we have a robust process to ensure that their certification status is kept current through scheduled calibrations.

Manufacturing Capabilities

Thorlabs continually invests in the expansion and modernization of our manufacturing capabilities. Our software provides real-time reporting on the status of our machinery, which ensures that our production output stays on schedule and meets our customers' needs. Below is a partial list of the vertical manufacturing capabilities available to our optomechanical design group.

From start to finish, any given component manufactured by Thorlabs is touched by more than a dozen people. Each person in the process is empowered to identify any potential quality issues regardless of whether it affects their operation. By embracing a total quality approach to our manufacturing, we strive to provide the highest caliber optomechanical components in the photonics industry.

3- and 5-Axis Vertical Mills

Vertical mills are an extremely versatile resource for Thorlabs. We use them to prototype designs, produce initial production runs as the main production line is tooled and validated, and as the main production resource for a wide range of components. Many of our vertical mills have some form of automation that allows them to operate continuously during a shift, and in some cases, between shifts. The automation solutions vary from simple two-pallet systems to 60-pallet systems that can be swapped in and out without tooling or setup.

Horizontal Mills

Thorlabs has invested extensively in the optimization of our horizontal milling centers for use in the photonics market. We have implemented tooling solutions that provide cost and quality advantages to our customers, whether they need a high volume of a single component or a large mix of components in low volumes. Once the initial investment is made in the fixturing and tooling, Thorlabs can efficiently machine the needed components and implement production ramps by duplicating the setup on additional spindles.

Swiss Screw Machines

Our Swiss Screw Turning Department specializes in single point turning applications. For example, we manufacture fine adjustment screws and bushings that are used in our own products as well as sold directly to our customers. The superior performance of a Swiss Screw Machine in terms of deflection and vibration of the material for small parts is important for components with demanding tolerances. This paired with our specialized vision system for turned parts allows us to design and manufacture solutions that a traditional lathe could not accomplish. Our Swiss Screw Machines are equipped with bar feeders that maximize production capacity, thereby minimizing costs.

Lathes

Our Lathe department is the main producer of turned components. We handle a wide range of bar stock and select new lathes optimized to specific components. In 2019, for example, we purchased a lathe with live tooling on both the spindle and subspindle. This addition enabled us to produce a large number of components in one operation, rather than needing to be turned and then milled. As a second example, in 2022, we purchased a lathe that had a small working volume and no live tooling options. The benefit of these features is a reduced cycle time on turned parts like our SM05 lens tube line. Carefully selecting the jobs that run and their order can significantly reduce the setup time and optimize the cost to produce a component.

Wire EDM

In 2018, Thorlabs added a Wire EDM Department, positioning us to manufacture components unable to be made using a mill or lathe. The wire EDM machine ablates conductive material by passing a current from a wire through the material being cut. Since this is a slow, non-contact method of removing material, the wire EDM machine can hold tolerances that would be difficult to hold otherwise. Additionally, the size of the features that can be created are only limited by the diameter of the wire. Material hardness is an advantage, not a limitation, of the wire EDM. The wire EDM can be used to cut hardened steel just as easily as aluminum.

Tumbling and Bead Blasting

While post-machining finishing processes typically receive little attention, we consider them integral to the final product. Our finishing departments have a range of tumbling and bead blasting options that let us remove tooling marks from aluminum and steel, while maintaining the dimensional tolerances of the component. These techniques produce mirror-like finishes on hardened stainless steel.

Passivation and Anodization

Thorlabs has fully automated passivation (for stainless steel) and anodization (for aluminum) lines in our manufacturing facility. Managing this capability in-house reduces lead times, enables tighter quality control, and optimize finishes for specific products or customers. Many of our vacuum-compatible products are made from stainless steel; by controlling what enters our passivation system, we can ensure that contaminants are never introduced into the passivation line due to a prior customer’s run.

CNC Grinding

The ability to CNC grind surfaces allows us to achieve the surface flatness and quality that are critically important to the performance of certain types of optomechanical products, such as linear stages.

Laser Engraving

Nearly all products are engraved with a logo, part number, or serial number. By having this capability in-house, we can control the cost and minimize the time it takes to perform the operation. Custom engraving is available for many components.

| Posted Comments: | |

sahanuoc

(posted 2016-04-25 03:12:13.28) Great! besembeson

(posted 2016-04-28 01:52:52.0) Thank You. |

Products Home

Products Home

Optomechanics Manufacturing

Optomechanics Manufacturing