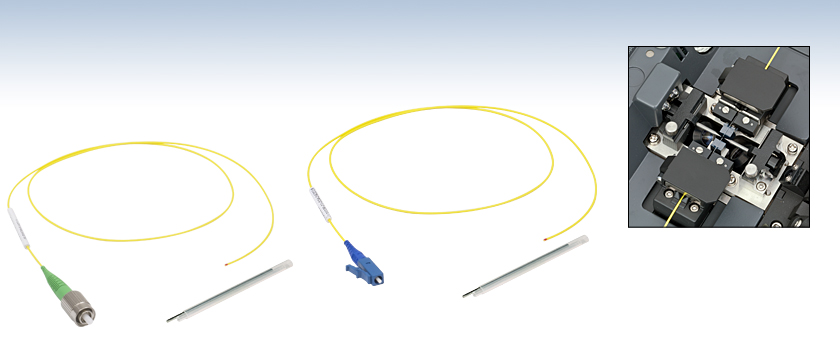

Splice-Ready Connectors

- Splice-Ready FC/PC, FC/APC, or LC/PC Connector with Splice Protector Sleeve

- No Polishing or Epoxy Needed

- Wavelength Range of 1260 - 1625 nm

- Splice Protector Sleeves Available Separately

Includes 60 mm Long

Splice Protector Sleeve

P9-SMF28E6-APC

P9-SMF28E6-LC

Splice-Ready Connector and

Fiber Mounted in a Fiber Splicer

(Fiber and Fiber Splicer Not Included)

Please Wait

Click for Details

Figure 1.1 Splice-Ready Connector and Fiber Mounted in a Fiber Splicer

Features

- Quickly Repair Broken or Damaged Fiber

- Available with FC/PC, FC/APC, or LC/PC Connector

- Splice Protector Sleeves Available Separately

Thorlabs' splice-ready connectors, also commonly called splice-on connectors, offer a quick and easy method to repair broken or damaged optical fiber. Designed for the 1260 - 1625 nm wavelength range, our splice-ready connectors are available with one of three industry-standard connectors: FC/PC, FC/APC, or LC/PC. Each connector includes 50 cm of SMF-28 Ultra single mode fiber, scissor cut on the spliceable end.

The connectors sold here include a 60 mm splice protector sleeve which provides rigid support for the splice joint. These sleeves are also available in lengths of 40 mm or 60 mm in packages of 25. The splice protectors are compatible with fiber outer diameters of 900 µm.

Thorlabs offers fiber-to-fiber splices, fiber cleavers, fusion splicers, and stripping & crimping tools for splicing fibers, ideal for our splice-ready connectors. Alternatively, our Vytran® fiber recoaters offer flexible, low-profile splice protection. For inquiries about custom splice-ready fibers, please contact Technical Support.

Splice-Ready Connector Specifications

| Item # | P9-SMF28E6-FC | P9-SMF28E6-APC | P9-SMF28E6-LC |

|---|---|---|---|

| Fiber | SMF-28 Ultra | ||

| Connector Type | FC/PC | FC/APC | LC/PC |

| Insertion Lossa | 0.3 dB | ||

| Return Lossa | 55 dB | 65 dB | 55 dB |

| Wavelength Range | 1260 - 1625 nm | ||

| Cutoff Wavelength | <1260 nm | ||

| Mode Field Diameter | 9.2 ± 0.4 µm @ 1310 nm 10.4 ± 0.5 µm @ 1550 nm |

||

| Numerical Aperture | 0.14 | ||

| Cladding | Ø125 ± 0.7 µm | ||

| Coating | Ø242 ± 5 µm | ||

| Jacket | Ø900 µm Yellow Hytrelb Tube | ||

Splice Protector Sleeve Specifications

| Specification | SPS40 | SPS60 |

|---|---|---|

| Sleeve Length | 40 mm | 60 mm |

| Stainless Steel Rod Length | 35 mm | 55 mm |

| Inner/Outer Tube Material | Ethylene-Vinyl Acetate | |

| Dimension after Shrinking | Ø3.2 mm × 40 mm | Ø3.2 mm × 60 mm |

| Temperature Range after Shrinking | -40 to 80 °C | |

Click to Enlarge

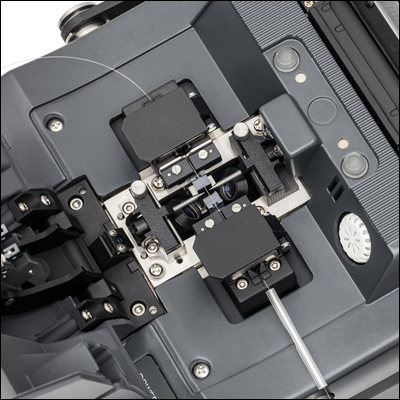

Figure 3.1 A spliced fiber in a fiber splicer. The splice protector sleeve can be seen in the bottom right of the image. When splicing together two connectorized fibers, thread one of the fibers through the splice protector sleeve before splicing.

Click to Enlarge

Figure 3.2 A spliced fiber with splice protector sleeve in the heating compartment of a fiber splicer. Once the fiber has been spliced together, slide the protector sleeve over the splice joint and place in the heating compartment of your fiber splicer. Refer to your operation manual to find the correct settings to properly heat the splice protector.

Figure 3.3 A completed spliced fiber with splice protector sleeve. When correctly applied, the splice protector will hold firmly in position while the stainless steel rod provides rigid support about the splice joint. This will help protect the splice joint as well as prevent any bending or flexing in or around the splice joint.

| Posted Comments: | |

jsauls

(posted 2016-03-16 16:37:58.29) Why are these splice ready connectors only available for high wavelengths? I need to replace a damaged end on this laser: http://www.thorlabs.us/thorproduct.cfm?partnumber=BL976-SAG300, but am not sure the best and most direct way to do so. besembeson

(posted 2016-03-17 11:51:01.0) Response from Bweh at Thorlabs USA: The splice-ready fiber connector includes the SMF-28 Ultra fiber designed for 1260-1625 wavelength range. Besides, you will also need a fiber splicer to use these. I will contact you regarding the BL976-SAG300 to determine if it is a dirty fiber tip or you need a connector replacement. |

- Quickly Repair Broken or Damaged Fiber

- Available with FC/PC, FC/APC, or LC/PC Connector

- Scissor Cut on the Spliceable End

- Wavelength Range: 1260 - 1625 nm

- Includes 60 mm Splice Protector Sleeves

Our splice-on fiber connectors offer the quickest pre-polished terminated pigtail in order to prepare the end splice; there is no polishing or epoxy necessary. To splice, simply strip the jacket off of the spliceable end, cleave, and splice together with the prepared end of the broken or damaged fiber. The image in the Overview Tab above shows our splice-ready fibers mounted in a fiber splicer. Splice sleeves are also included to protect the splice joint of the fixed fiber. Each package comes with six splice-ready fiber connectors and six splice sleeves. Extra splice protector sleeves are available below.

Click to Enlarge

Figure G2.1 Splice protector sleeve in fiber splicer

Click to Enlarge

Figure G2.2 Effects of heating on splice protector sleeves.

- Fits Fiber Outer Diameter up to 900 µm

- Available in Either 40 mm or 60 mm Lengths

- Ø3.2 mm After Shrinking

- Sold in Packs of 25

Thorlabs' Splice Protector Sleeves are designed to protect splices in fibers with an outer diameter up to 900 µm. These fusion splice protector sleeves are an economic solution that offers reliable and solid protection for splice joints. An outer shrink tube holds the tube through which the fiber is threaded as well as the strength member, a solid steel rod that provides rigid support for the splice joint. This design not only provides a replacement for the original fiber cable jacket, but also provides excellent rigidity around the splice joint, preventing the spliced area from bending or flexing.

To use, thread the fiber through the inner fiber tube of the sleeve. Position the sleeve so that the splice joint is in the middle. The sleeve must then be heated causing the outer shrink tube to contract to Ø3.2 mm. Proper heating is required to ensure an accurate fit and function of the splice protector sleeve. Figure G2.2 illustrates the effects of proper and improper heating on these sleeves. The top image shows normal heating; here the shrink tube is uniform across the splice, providing permanent and rigid protection. The middle image shows excessive heating; here the shrink tube shows evidence of blemishes and melts in the tubing. The bottom image shows insufficient heating; here the shrink tube is not uniform across the splice, resulting in loose or poor protection for the splice joint. A fiber splicer can be used to ensure proper heating of the sleeve (refer to the operation manual of your splicer for correct heating settings). Figure G2.1 shows a properly heated splice protector sleeve in a fiber splicer (see Splice Sleeve Guide tab for more information).

The clear outer tube of the splice protector sleeves allows the color of the optical fiber itself to be seen. These sleeves come in two standard sizes of 40 mm and 60 mm. They cannot be cut due to the steel rod that provides support for the splice joint. Custom lengths are available; please contact Tech Support for more information.

Products Home

Products Home

Zoom

Zoom

Splice-Ready Connectors

Splice-Ready Connectors