Fresnel Lenses

- Reduced Thickness and Weight Compared to Standard Lenses

- Ideal for Illumination and Light Collection Applications

- Four Focal Lengths Available

FRP0510

Ø1/2"

FRP125

Ø1"

FRP232

Ø2"

Fresnel Lenses (Right) Consist of Sections with

Similar Curvature to Standard Lenses (Left)

Please Wait

Click to Enlarge

Excel Spreadsheet with Raw Data

Figure 1.2 The shaded region in this plot denotes the spectral range over which we recommend using these lenses. All our Fresnel lenses have a nominal thickness of 1.5 mm, and only minor differences are observed for different focal lengths.

Click to Enlarge

Figure 1.1 Ø2" Fresnel Lens in 60 mm Cage System with LCPA1 Alignment Plate to Check Beam Diameter and Centration

| Limited Zemax Files |

|---|

| Click on the Limited Zemax Files Tab to access the limited Zemax file download. Our entire Zemax Catalog is also available. |

Features

- Focal Length of 10 mm, 25 mm, 32 mm, or 51 mm

- Optical-Grade Acrylic is Transmissive from 400 - 1100 nm (See Figure 1.2)

- Compact, 1.5 mm Thick Substrate Minimizes Absorption

- Used in Light Gathering, Illumination, and Homogenization Applications

Thorlabs' Fresnel Lenses offer light focusing and collimation without the bulk associated with traditional lenses. Our Fresnel lenses are effectively 1.5 mm thick across their entire diameter, and this uniform thickness, combined with the optical-grade acrylic substrate, reduces their weight by over 90% versus glass lenses of comparable focal length and diameter.* These properties make them ideal for building compact optical systems.

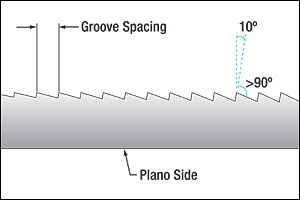

Our lenses are offered in 1/2", 1", and 2" diameters, and they provide high transmission in the 400 - 1100 nm spectral range (see Figure 1.2). As shown in the schematic at the top of the page, they consist of a grooved side and a plano side. In order to minimize the substrate thickness, stepwise discontinuities are introduced at regular radial spacings, creating grooves. Hence, Fresnel lenses can be thought of as a series of concentric rings.

Fresnel lenses are often used to homogenize the output of LEDs, focus light onto a point detector, or concentrate sunlight into solar cells. For the lenses sold on this page, each step has a 10° pitch (illustrated by the diagram in the Specs tab). This pitch angle causes distortions that make the lenses unsuitable for imaging applications.

To mount our Fresnel lenses, we recommend using our LMR05(/M), LMR1(/M), or LMR2(/M) Fixed Lens Mounts, which use a retaining ring to secure the optic. Do not overtighten the retaining ring since this may cause the grooves to wear. Our rubber Stress-Free Retaining Rings can be used in place of the standard aluminum rings to reduce the stress on the optic surface. The grooved side of the lens should be oriented to face the collimated beam, and the plano side should face the divergent source. The JEL10 Eye Loupe can help determine which side of the lens is grooved. Since the lenses are only 1.5 mm thick, they are too thin for mounts that hold optics with setscrews.

Thorlabs also offers aspheric condensers with diffusive surfaces that provide uniform illumination in the far field, as well as a complete selection of lenses.

*Weight reduction calculated by comparison to our Aspheric Condensers with Diffusers.

| Item # | FRP0510 | FRP125 | FRP232 | FRP251 |

|---|---|---|---|---|

| Focal Length | 10 mm | 25 mm | 32 mm | 51 mm |

| Focal Length Tolerance | ±5% | |||

| Diameter | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50.8 mm) | 2" (50.8 mm) |

| Diameter Tolerance | ±0.125 mm | |||

| Thickness | 1.5 mm (Nominal)a | |||

| Thickness Tolerance | ±0.25 mm | |||

| Clear Aperture | >90% of Diameter | |||

| Groove Spacingb,c | 0.10 mm | 0.25 mm | 0.2 mm | 0.23 mm |

| Pitchb | 10° | |||

| Design Wavelength | 588 nm | |||

| Refractive Index | 1.49 | |||

| Abbe Number (VD) | 55.3 | |||

| Parallelism | <3 arcmin | |||

| Surface Quality | 80-50 Scratch-Dig | |||

| Substrate Material | Optical-Grade Acrylic | |||

Click to Enlarge

Figure 2.1 This schematic defines the groove spacing and pitch angle in our Fresnel lenses. Note that the lengths are not to scale.

Click to Enlarge

Excel Spreadsheet with Raw Data

Figure 2.2 The shaded region in this plot denotes the spectral range over which we recommend using these lenses. All our Fresnel lenses have a nominal thickness of 1.5 mm, and only minor differences are observed for different focal lengths.

The linked Zemax files are a theoretical approximation of the performance of each lens. In place of a grooved structure, each file models a sloped surface with infinitesimal thickness at each radial position. This creates limitations, including the inability to view scattering information due to the pitch and groove spacing of the lens. In addition, the optical coefficients in each file are not from the data used at manufacturing; the coefficients are calculated using the necessary optical prescription to focus collimated light at the proper axial distance from the back surface of the lens. These limitations reduce the realistic modeling of the Fresnel lenses sold below.

| Posted Comments: | |

Tig CM

(posted 2025-01-07 08:23:13.617) Hello,

could you please give me a few figures for the chromatic behaviour of these lenses, especially longitudinal ?

Thanks,

Tigrane EGies

(posted 2025-01-09 12:30:43.0) Thank you for contacting Thorlabs. The transmission vs wavelength for the Fresnel lenses can be found in the “Overview” tab on the web: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1222. The longitudinal chromatic aberrations that result from these Fresnel lenses can be simulated using the limited Zemax files: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1222&tabname=limitedzemaxfiles. I have reached out to you directly regarding your specific application requirements. Michael Valasek

(posted 2022-06-24 09:25:09.22) Hello,

I was considering this product for our design however I would need to know what is degrade rate over time if placed into ambient temperature of 70C?

Thank you,

Best Regards,

Michael Valasek cdolbashian

(posted 2022-07-06 11:49:21.0) Thank you for reaching out to us Michael. While we do not have a rate of decay for these components, the optical grade acrylic has a high-end operating temperature of 80C so the 70C should be fine without other external conditions being applied: high pressure, stress, chemical exposure etc. user

(posted 2022-05-19 19:09:45.607) Hello,

Using a fresnel lens, does it enlarges the light source spot size? Is the output spot size limited to the effective diameter of the lens? cdolbashian

(posted 2022-05-20 04:54:14.0) Thank you for reaching out to us with this inquiry. The behavior of fresnel lenses can be estimated well via the thin lens equation. The diameter and divergence of the output light through the lens will depend on the position of the light source with respect to the fresnel lens, the size of the light source and the focal length of the lens. user

(posted 2021-05-19 09:09:37.927) Hi! Could you specify a glass transition temperature for the "optical-grade acrylic" used in construction of these lenses? YLohia

(posted 2021-05-26 03:34:26.0) Hello, thank you for contacting Thorlabs. Unfortunately, we do not have a spec for this parameter. Please note that the maximum service temperature for these acrylic lenses is 80C. user

(posted 2020-12-09 14:28:44.867) Hello. Similar to lenses with coatings, was there a laser induced damage threshold study? I was curious about the maximum fluence (J/cm^2) that can be used with these Fresnel lenses. YLohia

(posted 2020-12-14 02:25:41.0) Hello, thank you for contacting Thorlabs. Unfortunately, we do not have damage threshold test data on these lenses. Since these are uncoated acrylic lenses, the information on damage thresholds found in literature for this material should provide a reasonable estimate. alst

(posted 2018-08-16 09:03:29.103) Hi,

The zemax files don't seem to work, there is an error saying 'invalid edge thickness on surface 1'. What's the reason for this?

Regards,

Alfred YLohia

(posted 2018-08-29 02:23:43.0) Hello Alfred, thank you for contacting Thorlabs. We have tried all of the Zemax files on this page and found all of them to be working perfectly fine. What product are you referring to specifically? Could you please send a screenshot of the issue to techsupport@thorlabs.com? What version of Zemax are you using and with what operating system? Is there another machine you can try this on? I have reached out to you directly to troubleshoot further. anne.cournol

(posted 2016-12-08 09:14:26.8) Is the Fresnel Lenses material compatible with ultra vacuum ? tfrisch

(posted 2016-12-14 01:14:53.0) Hello, thank you for contacting Thorlabs. Unfortunately, acrylic is not a material suitable for vacuum use. I apologize for the inconvenience. user

(posted 2014-09-10 00:26:49.39) What is the maximum operating temperature of your fresnel lenses? besembeson

(posted 2014-09-12 03:41:25.0) Response from Bweh: The maximum operating temperature of our Fresnel lenses is 80°C. ralph

(posted 2014-06-10 12:08:01.367) Do you have the lens design parameters for FRP232? Specifically spherical base curvature, depth of annular zones. A Zemax or similar file would be great. myanakas

(posted 2014-07-03 05:17:19.0) Response from Mike at Thorlabs: Thank you for your feedback. Limited .ZAR and .ZMX Zemax files have now been added to the web in the "Limited Zemax Files" tab and in the supporting documents found by clicking the red "Docs" icon. The linked Zemax files are a theoretical approximation of the performance of each lens. We could not show the full structure as this information is proprietary to the manufacturer if the Fresnel lenses. We apologize for any inconvenience this may have caused. |

Products Home

Products Home

Fresnel Lenses

Fresnel Lenses