Our Sustainability Journey

Please Wait

Our Initiatives

Product Packaging

- All new products undergo a sustainable packaging analysis to ensure we use eco-friendly packaging where possible.

- We are reimagining our packaging for many products and implementing recycling and return programs.

- Our new fiber spools (see tab) are made with 100% recycled plastic, 55% less fossil fuels, 31% less water, and 67% less GHG emissions.

- Our new optics boxes (see tab) lower impact on climate change and energy consumption by using recyclable materials.

Manufacturing and Facilities

- We conduct energy audits to evaluate and implement energy efficient solutions in manufacturing facilities.

- We are installing dark sky friendly exterior lights at our Optics and Fiber facility in Newton, New Jersey to have a lesser impact on nocturnal wildlife.

- We have onsite electric car charging stations at our buildings in New Jersey, Germany, and the UK.

Shipping

- We offer a "Ship Complete" option to reduce the

number of packages shipped from a single order. - We are transitioning from plastic packing materials to paper where appropriate.

- We are testing reusable containers for intercompany shipments.

- UPS Carbon Neutral shipping is available for all orders in the U.S. and Europe and we are exploring similar options with other carriers.

Energy Use

- We use 100% renewable energy at our facilities in New Jersey, Michigan, Virginia, Colorado, Maryland, and Germany.

- Our virtual IT services save 167 metric tons of carbon dioxide equivalent (MTCO2e) annually.

- We have onsite electric car charging stations at our new buildings in New Jersey, Germany, and the UK.

We have the ability and responsibility to put our environmental and social sustainability values into practice. We recognize and accept the responsibility to improve the efficiency and impact of our manufacturing and distribution practices and to develop a sustainable lifecycle for our products.

More than Net Zero: Our ultimate goal is to be a net good for the planet.

A Letter from Our Leaders

The world can’t wait. If there was any doubt, the 2021 Intergovernmental Panel on Climate Change (IPCC) report made it clear we are facing an imminent and existential threat to the enduring health and wellbeing of the earth and all living beings who call this planet home. As sea levels rise, weather patterns intensify, and the unique and beautiful diversity of our natural world shrinks species by species, many of us have felt grief and fear for our collective future.

We must turn that emotion into action. As the owners of Thorlabs, a privately held and family-owned company, we have the privilege and responsibility to put our environmental sustainability values into practice. We know that we do not stand alone and that many of you deeply hold these beliefs as well.

While we’ve implemented some sustainable practices over the years at Thorlabs, including a recent and ongoing shift to more sustainable product packaging as well as enhanced environmental standards in our manufacturing facilities, we know there is still more work to be done.

We will be embarking on an ambitious environmental sustainability journey over the next few years. It is our goal to build a transparent, science-based roadmap to a resilient and regenerative future – we have a bold vision for Thorlabs in which we accomplish net good for the planet, not just offset our negative impact to achieve net-zero.

Our hope is that our company’s journey to more sustainable practices helps create a safer and more equitable environment for all – we know that climate change and environmental racism disproportionally impact communities of color and indigenous people. Our commitment to inclusion and racial justice is tied to our commitment to environmental and climate justice.

As a manufacturer, we know that our current business practices produce greenhouse gas emissions and material waste. But as a vertically integrated company, we are uniquely positioned to identify the full scope of our supply chain, the impact it has on the planet, and to transform our business to support a resilient future.

In addition, we will look for collaborations and partnerships where our products and technologies may be part of the solution – from environmental monitoring and sensing to renewable energy and carbon capture. As technologists, engineers, and scientists, we believe in the transformative potential of human ingenuity.

In the months to come, we will be developing and publicly communicating a clear, auditable, and inclusive strategy to ensure responsible practices at Thorlabs that will positively impact our global communities. The work begins now – we hope you will join us.

Sincerely,

Jenn Cable, President & Alex Cable, Founder and CEO

Thorlabs, Inc.

Optics Packaging Redesigned

Have Questions?

Our sustainability experts are here for you!

If you have any questions about Thorlabs' current sustainability efforts, please reach out!

Click the Contact Us button to send us an email. We'll get back to you within the next business day.

Click to Enlarge

Figure 3.1 Our BXM1 optics case is made from recyclable steel and includes a recyclable paper cushion with a small plastic insert to protect the optic inside.

Welcome! We began using new sustainable packaging for some of our optics in the summer of 2023. You may notice more of the new packaging over time as we expand our use of sustainable packaging. There will be several varieties, tailored to the distinct needs of different optics. Our new packaging minimizes the impacts of manufacturing and disposal while increasing the opportunities for reuse.

Please review the below information on the improvements we have made and let us know what you think by filling out the form on the Feedback tab, emailing us directly at packaging@thorlabs.com, or tagging us in a social media post.

Learn More in the Sections Below

Let Us Know What You Think on Social Media

Improved Sustainability

For years, Thorlabs has shipped optics in polystyrene (#6) plastic cases with a permanent label, plastic inserts, and foam cushions. Polystyrene is not recyclable in most areas, and the size of the case is smaller than the minimum size required by most municipal recycling facilities (2” x 2” x 2” or 5 cm x 5 cm x 5 cm).

We evaluated a variety of materials to replace the plastic case and found most of the sustainable options did not provide adequate protection, prevent dust, or ensure the case could be reused in a standard lab environment. After weighing all the options, we found that the best balance of sustainability, reusability, product protection, and ease of disposal came from a metal box with inserts that change depending on the optic. These changes will take us some time to complete, so you will continue to see some plastic packaging for a little longer. We appreciate your patience during this transition.

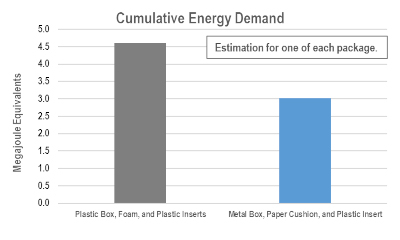

Our new packaging is primarily curbside recyclable, uses about 49% less fossil fuels, 64% less water, and 35% less energy during its lifecycle than our plastic optics packaging. Based on our typical annual usage, that could save as much gasoline as taking 29 average US cars off the road for a year, avoiding 27,000 showers, or powering about 23 average US homes for a year.

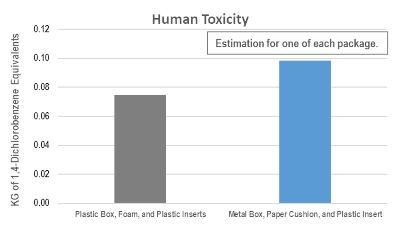

The human health impact has increased, as shown in the Human Toxicity chart, due to the mining and processing of metal. We also expect this impact to be reduced by our new return & reuse program. Reaching a reuse rate of 3% or more would be enough to mitigate this impact significantly. We have additional changes planned that will provide further reductions and are hopeful that it will be totally negated once our implementation process is complete.

We used ecoinvent and openLCA to perform a cradle-to-grave Life Cycle Analysis (LCA), which gave us the results we described above and the numbers used in the charts. We used regional averages and some assumptions. All values provided here are our best estimates. The results plotted here quantify the impact from each package assembly. We hope to share plastic-free packaging with you in the future. We hope you are as excited as we are to see additional changes soon!

Reuse

Reuse of the packaging was a key component of the design. We’ve included an internal hinge that does not shatter after a drop (like the plastic ones can), an embossed lid that nests into the bottom of a second case and prevents stacked cases from toppling easily, and a peelable label.

Reusing the optics boxes will reduce their environmental impact. If you won’t be reusing your boxes in the lab, we would love to take them back and reuse them! We will inspect, clean, and use them to repackage new optics for our customers.

We performed an analysis to confirm that our reuse is sustainable. The sustainability depends on how many boxes are returned and reused annually. That means the more the merrier, so please don’t be shy! The travel distance and number of boxes in a return shipment are less important factors. Even with a small number of returns and a long travel distance, our analysis shows a 1 to 16 percent decrease in resource use and pollution.

We will pay for the return shipping. For instructions, please email Lindsay at packaging@thorlabs.com, or contact your customer service representative.

If you no longer need the box for the original optic, please consider using it for another purpose, returning it, or recycling it. We would love to see examples of what you find useful. We sincerely hope the packaging will be useful to you for many years, either for storing optics or other odds and ends in your lab.

Disposal and Recycling

If you would like to recycle the BXM1 steel box instead of reusing or sending it back, please remove the paper inserts, peel off the label, and deposit the box with other metal or steel recycling. The paper cushion can be recycled with your local paper recycling service. Unfortunately, the lens tissue cannot be recycled or composted and must be thrown away. The small plastic insert is #7 PETG and can only be recycled if your recycler accepts PETG and has no minimum size requirement.

In our classic plastic packaging, the box is made from #6 plastic (polyethylene), the foam is #4 plastic (LDPE), and the plastic insert is made from #7 PETG. If your recycling facility accepts those plastics and has no minimum size requirement, you can separate the components and recycle them. If they’re not acceptable at your local facility, please discard them.

Small Fiber Spools Redesigned

Have Questions?

Our sustainability experts are here for you!

If you have any questions about Thorlabs' current sustainability efforts, please reach out!

Click the Contact Us button to send us an email. We'll get back to you within the next business day.

Click to Enlarge

Figure 4.1 Our new spool is made from a plastic that is commonly accepted for recycling – and it can be reused!

As part of our sustainability efforts, we are using new spools for most of our fiber. If your spool has a QR code on it, you have received one of the new spools!

We have assessed various options to replace our existing #7 ABS* spools. The new spools use 100% recycled #2 HDPE** plastic, which is easier to recycle. They're also smaller and lighter than our previous spools, which reduces greenhouse gas emissions during shipment!

Please review the below information on the improvements we have made and let us know what you think by filling out the form on the Feedback tab, emailing us directly at packaging@thorlabs.com, or tagging us in a social media post.

Learn More in the Sections Below

Let Us Know What You Think on Social Media

*ABS (Acrylonitrile butadiene styrene) is a #7 plastic and is not commonly accepted for recycling.

**HDPE (High Density Polyethylene) is a #2 plastic and is more commonly accepted for recycling.

Improved Sustainability

Thorlabs has been using spools made from ABS #7 plastic and HIPS* #6 plastic with foam cushioning for many years. ABS and HIPS plastics are not recyclable in most places, so we evaluated a variety of materials to replace the spools. Paper-based options didn’t pass our testing, and metal-based options were worse when we calculated the impacts they would have on the environment. So, we decided to stick with plastic for now – but make it more sustainable!

The new small spools are made from #2 HDPE plastic, which is more commonly accepted for recycling. Also, the foam is removable which makes recycling much easier! These spools are about 41% smaller in size and weigh a little less than our previous small spool, which will result in reduced greenhouse gas (GHG) emissions during shipment.

Together, these changes mean that our new spools use about 55% less fossil fuels, 31% less water, and create about 67% less greenhouse gas (GHG) emissions during their lifecycle than our previous spools. Based on our typical annual usage, the new spools could save the equivalent of 800 US GL (3,000 L) of petroleum, 15,300 US GL (58,000 L) of water, and enough energy to power roughly 3 homes in the US for one year than if we were to continue using our previous small spools.

We used an ecoinvent 3.8 database in OpenLCA to perform a Life Cycle Analysis (LCA) using ISO 14040 & ISO 14044 guidelines. You can learn more about LCA here. Our calculations indicate the results we described above and the values used in the charts. We used regional averages for the manufacturing processes and transportation averages that reflect our sales. The results plotted here quantify the impact from one package assembly: spool, foam, cardboard shipping boxes, labels, and artwork. The GHG emission equivalences were based on the USA Environmental Protection Agency’s Greenhouse Gas Equivalencies Calculator.

*HIPS (High Impact Polystyrene) is a #6 plastic and is not commonly accepted for recycling.

Reuse

Our new spools are reusable too! We would be happy to take them back. Upon receipt, we will inspect, clean, and reuse to package new fiber for our customers.

Our environmental analysis indicated that mailing our spools back for reuse is sustainable, regardless of where you are. We expect that reuse of the new spools will reduce the greenhouse gas emissions, water ecotoxicity, and fuel use by as much as 14%, depending on travel distance and return rate.

The more people mail them back, the more sustainable the program becomes, so don’t be shy! This is true whether you’re located close to or far from one of our locations.

To send the spool back, please email us at packaging@thorlabs.com for instructions.

Disposal

#2 HDPE Plastic can be recycled by most facilities. Please check if your recycler has size restrictions on plastics they accept. If your recycler accepts buckets, they will likely accept our spools (similar size and properties). These might also be recyclable in lab recycling programs such as Terracycle or Polycarbin.

Before recycling please remove the foam by cutting it anywhere along the barrel and peeling it off.

Check if your facility recycles Polyethylene foam. As foam is only recyclable at select recycling facilities, we are working to eliminate our use of this packing material.

| Posted Comments: | |

user

(posted 2025-07-18 13:21:40.91) This is feedback on new packaging, probably a bit too late. Recyclable paper cushion is a nightmare. Due to the new packaging, brand-new optical components often arrive with significant dust contamination on their surfaces—dust that originates from the recyclable paper cushioning itself. If this dust remains on the optics for an extended period, it can become difficult or even impossible to remove completely. In contrast, the previous packaging was significantly more effective and reliable for protecting optical components during storage and transport. aprokofiew

(posted 2025-07-21 11:15:00.0) Thank you for sharing this feedback with us! If you are referring to an optic received in the metal box, the previous paper inserts that shed lint contamination were phased out in the beginning of this year. The Glassine Paper or lens tissue should not be causing any contamination. Feel free to reach out to tech support with any more details, if needed. Zhou Li

(posted 2024-06-20 07:40:45.237) Hi,

I noticed you have changed your optics packing. And I really appreciate this kind of environmental behavior.

However, there's one problem. There are always a lot of small debris inside the box. I don't know whether it comes from the paper cushion or something else. What's worse, the debirs stick to the surface of the optical element, and it's hard to get removed using clean air duster. I'm afraid those debris may do damage to the surface of the optics. Maybe you can do something about it? Please help find out where these debris come from and solve the problem.

Thank you! cdolbashian

(posted 2024-07-01 02:49:54.0) Thank you for reaching out with this feedback. As we have been seeing this type of feedback more often recently with respect to the paper packaging, we will be returning to plastic inserts within recycled metal containers. In the meantime, we are returning to the proverbial "drawing board", in an attempt to find a new long-term sustainable packaging solution. user

(posted 2024-05-08 19:50:40.44) The new sustainable optics packaging is good in theory, however the shiny metal box is not suitable for use in laser labs where unwanted reflective surfaces are generally minimized as much as possible. The cardboard/paper optics holder inside also leaves a large amount of fiber residue on the surfaces of the optic, which is also not ideal. We appreciate the steps towards a greener manufacturing process, but these issues are concerns cdolbashian

(posted 2024-05-09 04:05:12.0) Thank you for reaching out to us with this feedback! We are always seeking to serve our environment and our customers to the best of our abilities. The feedback regarding the fiber residue is well received, and we are looking into alternative sustainable packaging which can potentially replace this fibrous paper in order to avoid the type of contamination which you are experiencing. Please feel free to email our packaging team (Packaging@thorlabs.com) for further updates on this. This kind of feedback is always appreciated! Thibault Capelle

(posted 2023-05-30 08:20:27.83) Dear Thorlabs,

This sustainability statement is in stark contrast with your stupid "Lab snacks" policy, which creates an enormous volume and weight shipping carbon footprint that virtually every teams around the works have noticed and complained about. You clearly put a stupid commercial policy before the climate in your priority list. Please consider stopping this if you really believe your statement.

On top of the shipment footprint, the content of this junk food is full of meat snacks that have an extra carbon footprint that could be avoided for free by choosing different snacks.

Moreover, the extra boxes with the "I reused this box for ..." is a complete greenwashing statement since no effort is put by you to get those boxes back to be reused by you, so they just accumulate in labs before being sent to recycling for nothing: we do not have as many use cases for box reusing as you do, so if you keep the lab snacks, which is already a terrible idea, it is your job to reuse them, not ours, please do not individualize the responsibility on climate impact.

Besides, the mention of "carbon neutrality" is also a greenwashing statement that has been debunked by many associations over the year (see for instance https://carbonmarketwatch.org/publications/corporate-climate-responsibility-monitor-2023/). You would instead be better off developing a transparency policy: where are your warehouses, where are shipments made from, and what is the carbon footprint of each of them? For this footprint, you should also put other numbers to have an easy comparison: what is the carbon footprint of an intercontinental air travel for a conference for example? Also, what is the complete story behind each product, where are the mineral extracted and refined? What about the transportations from all those primary refining places to the previously mentioned warehouses? What is the carbon footprint of this? Only such a policy could be seen as an initial building block towards a more sustainable company.

I hope that this message will be read and acknowledged, although I am well aware that only a democratic process inside your company would make this kind of proposal applied, and I do not expect Thorlabs employees to have even a word to say in the global strategy of their company.

However, I hope that as scientists yourselves, you understand the huge effort private companies have to undergo to limit the destruction of the planet, and that you understand that what I adressed here is barely scratching the surface of your real impact.

Best regards,

Thibault CAPELLE cdolbashian

(posted 2023-06-02 03:35:16.0) Thank you for reaching out to us. While we have received much positive feedback about our Lab Snacks, we understand that they are not universally popular. Please let us know when you place your next order that you do not wish to receive a box as we include the free snacks by default. The type of snacks included has been left up to the local teams which are fulfilling the orders. For instance, orders fulfilled at our Newton location receive primarily plant-based snacks. Your order came from Germany, and we have now reached out to them regarding their choice of snacks.

We are currently in the process of undergoing our Scope 3 emissions inventory after which time we will announce our emissions reduction targets through the Science Based Targets initiative (SBTi). SBTi is a partnership between the Carbon Disclosure Project, the United Nations Global Compact, World Resources Institute, and Worldwide Fund for Nature which defines and promotes best practice in emissions reductions and net-zero targets in line with climate science. If you are interested in learning more about these targets as they relate to our business practices, our warehouse locations (also available here: https://www.thorlabs.com/locations.cfm), or are curious about our employee-led global Green Teams and the localized projects they are working on, please feel free to contact GoGreen@thorlabs.com. Maxime Bès

(posted 2023-04-28 03:18:48.783) I ordered some products, for a total weight of 20 g.

I received my products, plus 460 grams of snacks that I did not ask for. On total, the weight you carried is almost 25 times the weight that needed to be carried away.

I quote :

1) "We conduct an annual greenhouse gas (GHG) emissions survey"

2) "Energy efficient solutions are evaluated and

implemented in all new manufacturing facilities"

3) "We offer a "Ship Complete" option to reduce the

number of packages shipped from a single order"

4) "We are transitioning from plastic packing materials

to paper wherever appropriate"

5) "We are testing reusable containers for intercompany shipments"

You should remove this in order to remove energy.

Best regards,

Maxime cdolbashian

(posted 2023-04-28 03:51:14.0) Thank you for reaching out to us with this feedback. I am sorry that you have had this negative experience as we strive for customer satisfaction as one of our core pillars. We are happy to omit such extras from your shipments in the future, please let us know when you are placing an order, as we include the free snacks/gifts by default. |

Products Home

Products Home

Sustainability

Sustainability