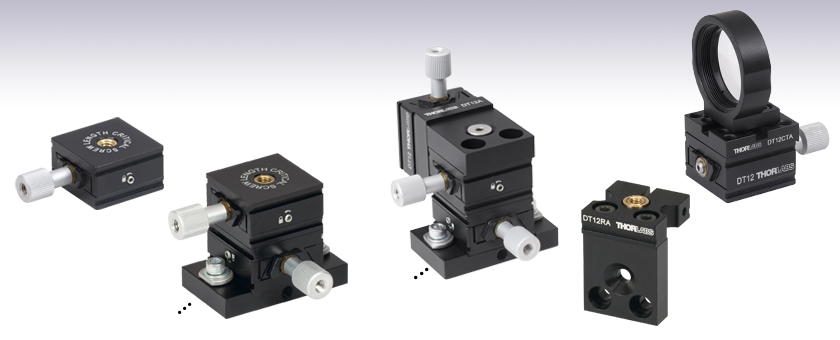

1/2" (12.7 mm) Travel Miniature Dovetail Translation Stages

- Modular, Compact Design

- Lockable Moving Platform

- Rapid, Smooth Positioning

DT12

Compact Dovetail Translation Stage

DT12B

Base Plate Included

Application Idea

A DT12 Stage with a DT12CTA Top Plate and CT101 Optic Mount

DT12XYZ

3-Axis Dovetail Translation Stage

DT12XY

2-Axis Dovetail Translation Stage

DT12RA

360° Rotation Adapter

DT12B

Base Plate Included

Please Wait

| DT12 Stage Specifications | |

|---|---|

| Travel Range | 0.5" (12.7 mm) |

| Maximum Load | Horizontal: 2.5 lbs (1.2 kg) Vertical: 0.55 lbs (0.25 kg) |

| Travel per Revolution | 0.014" (0.35 mm) |

| Construction | Aluminum with Precision Steel Leadscrew |

| Dimensionsa (Including Actuator) | 1.00" x 1.81" x 0.58" (25.4 mm x 45.9 mm x 14.8 mm) |

| Mounting Hole Threadingb | 8-32 (M4) |

Features

- Single-Axis, XY, XZ, and XYZ Configurations Available

- Compact Footprint: 1.00" x 1.81" (25.4 mm x 45.9 mm)

- Dovetail Mechanism Provides Smooth Travel and Long Lifetimes

- Lockable Moving Platform

- Ø1/2" Post Mountable

Click to Enlarge

DT12 Stages are Post Mountable via a Bottom-Located 8-32 (M4) Mounting Tap

These Dovetail Translation Stages are compact, entry-level positioners, ideal for use in applications where space is limited. Each stage has a 1.00" x 1.00" (25.4 mm x 25.4 mm) platform that can be translated up to 1/2" (12.7 mm) using a precision M3 x 0.35 adjuster. The moving platform can be locked using a side-located setscrew and 0.05" hex key.

An 8-32 (M4) tap on the bottom of the stage allows it to be mounted on Ø1/2" posts, while a top-located

8-32 (M4) tap is for mounting optical components, top mounting plates, or accessories. Each stage includes mounting grooves on the top and bottom of the stage to attach to an optical table using two CL6 Clamps (sold separately).

Four stage configurations are available: single-axis, XY, XZ, and XYZ. In order to guarantee orthogonality of the axes, XY configurations must be ordered preconfigured from Thorlabs. Pre-configured multi-axis stages also include a base plate for mounting the stages to an optical table.

| Dovetail Translation Stages |

|---|

| 1/2" (12.7 mm) Travel |

| 1" (25 mm) Travel |

| 2" (50 mm) Travel |

Accessories

A top mounting plate adapter is available that includes an array of 4-40 (M3) and 8-32 (M4) mounting taps and keyways that facilitate the mounting of our 30 mm cage stage accessories. Slotted base plates for mounting the stages to an optical table are supplied with all 2- and 3-axis configurations, but are also available separately for single-axis stages. A right-angle bracket allows the stages to be easily assembled into XZ, YZ, or XYZ configurations, while a rotation adapter can be added to rotate a single stage up to 360°. In addition, a cage system adapter is provided for mounting a stage using 60 mm cage rods.

| Posted Comments: | |

Guseon Kang

(posted 2024-01-16 19:30:49.07) I would like to use the DT12 in an XY configuration. To do this, should I purchase two DT12s and connect them with an M4? A precise guide on the necessary components for setting up an XY configuration would be helpful.

Conversely, is it possible to separate a DT12XY into two separate DT12 units for single-axis use each? Thank you Michael Born

(posted 2023-07-06 18:04:19.557) I have several DT12/M that I would like to use in vacuum (10^-3 or 10^-6mbar).

Has anybody tried to disassamble, clean (ultrasonic bath) the translation stage and then apply Thorlabs Vacuum Grease or Thorlabs Apiezon Grease?

Would this work?

I want to XY position a 0.5" optical element in vacuum.

A POLARIS-1XY solution would be larger and much more expensive... fguzman

(posted 2023-07-10 10:11:30.0) Thanks for your enquiry. Unfortunately these stages are not vacuum compatible, and disassembling them would void the warranty. Even if possible reassembling them, they would not give you the spec values stated on our website. I will contact you directly to discuss your application. Chiara Toschi

(posted 2023-04-28 11:51:00.193) I'm a postdoc at the University of Oxford and use your fantastic stage to position mice on a rig. We always want to position them in the same way however we have to change position for each mouse because each mouse is different (size-wise). It would be very useful to have a metric right next to the handles to be able to write down the coordinates of the position of each mouse, we now have to attach tape next to the handles to have a reference system of where the position of the animal was last time we trained. So I think it would just be super helpful to have printed on the stage metrics/numbers/reference points on the XYZ axes. Not sure if I explained this very well, let me know if you want a picture of we are doing. fguzman

(posted 2023-05-03 07:06:46.0) Hi Chiara, thanks for contacting Thorlabs. We are glad to see this stage is helping you in your research. We have taken note on your suggestion, thanks for sharing this idea. We have passed this to our engineers. I will contact you directly to further discuss your application. David Gherardi

(posted 2019-06-11 12:11:32.747) Hi Radu. Thanks for your response. I didn't explain myself very well. The tapped M4 holes on the DT12XYZ/M (and I assume the other stages of this type) are very shallow (spec = 3.6mm). Your posts come with a 12mm set screw which are spec'd to protrude a minimum 4.6mm from the post (too long for the 3.6mm hole). Not a big issue of course, just frustrating when you open a new stage and can't use it without ordering shorter screws. rmiron

(posted 2019-06-12 05:12:09.0) Dear David, thank you for clarifying the problem and for bringing it to our attention. I will see to it that we will start providing short screws with DT12XYZ(/M). Radu David Gherardi

(posted 2019-06-07 04:30:13.42) It would be good if the stages came with an appropriately short M4 screw(s) to enable mounting to standard 1/2" posts. rmiron

(posted 2019-06-07 05:33:21.0) Response from Radu at Thorlabs: Thank you for your feedback. The reason we don't supply M4 screws with these stages is because our 1/2" posts already come with an M4 screw. With that being said, such screws are easy to lose and additional ones would not hurt. I have relayed your message internally. ludoangot

(posted 2018-11-08 18:00:34.333) The DT12 is a great and convenient little stage for which I find many applications. One of the latest is to use it to add a translation axis to your XYFM1 (XYF1) target holder, making the holder a compact XYZ stage. Unfortunately both the target holder and the DT12 have threaded holes so alignment between the target holder and the stage required me to find a shim of the right thickness. What could be done to easily mount the DT12 on the XYFM1 (or XYF1)? I'm thinking of a mini mounting plate such as the DT12CTA but with counter bored holes, do you offer anything similar? rmiron

(posted 2018-11-12 06:31:13.0) Response from Radu at Thorlabs: Thank you for your feedback. An adaptor plate with a footprint that is larger than the dovetail stage's footprint would eliminate this problem. Until we add such a plate for DT12 in our product range, I recommend that you try using our universal base plate (UBP2). cbrideau

(posted 2018-04-18 11:42:47.633) Could the location information of the two countersunk screw holes be added to the drawings for the DT12A? I would like to use it to secure an LED assembly at an angle to one of these stages but the position of the two countersunk holes is not shown on the drawings. bhallewell

(posted 2018-04-20 08:38:21.0) Response Ben at Thorlabs: Thank you for your feedback response. I've passed your feedback onto our Engineers. I will contact you to advise you on the locations of the counterbored screw holes. nkaddy

(posted 2017-02-22 04:53:50.66) RE: DT12XYZ/M

Just to be clear I will call the bottom translator Y, the middle X and front Z. Can you clarify if the X adjustment screw can be mounted onto the opposite side of the stage. As shown in the picture it is on the left. I need to have it on the right, because I want to put two of these next to each other and the micrometer screw would impede their closest placement (and access). bhallewell

(posted 2017-02-24 07:00:42.0) Response from Ben at Thorlabs: This is something that we could produce for you as a special. The stage will need to be aligned on a jig & glued in place during production. I will contact you directly to discuss a quote. ludoangot

(posted 2016-10-24 14:51:30.9) Hello, I've just received my DT12/M. The little trapezoidal plastic part at the end opposite to the knob has some rotational play, and when the stage is translated so that this plastic part is left exposed, this part have rotated and prevents (blocks) the stage from being translated back to its original position. This means that whenever I want to go past beyond this position I have to manually adjust the rotation position of the plastic part. Is this normal? Also when the DT12/M is used as illustrated on the images of this page (i.e. with the brass female thread on top), a clockwise rotation of the knob leads to the stage moving backward, which is rather unusual. Finally the DT12/M didn't come with the hex key as mentioned (but that is a minor issue). bhallewell

(posted 2016-10-24 10:45:05.0) Response from Ben at Thorlabs: Thank you for contacting us about this problem. This is certainly not typical behaviour & I will contact you directly to check the best way to get you a functioning stage. With regards to the included hex key, this is something that we no longer provide with this stage in an effort to reduce waste. Hex key kits can be purchased separately from the following webpage if these are needed.

https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=1407

We will ensure that this reference to an included hex key is fixed within our product manual. p.j.denissen

(posted 2016-04-23 11:42:43.01) What is the required torque you have to expose to the lead screw and what is the play/accuracy of the stage? cevered

(posted 2016-04-28 06:24:59.0) Thanks for using our feedback tool. We will contact you via email directly with further information about DT12 specifications. c.wilson

(posted 2013-05-01 02:14:08.217) I hope I am not being silly, but I am confused by the application idea pictured above (showing the DT12/M dovetail stage connected to the RC1 rail carrier). How are the two connected together? The mounting hole on the RC1 is a M6 or M4 (with SD1 adapter ring). In the image this seems to be connected to the thru hole on the DT12/M, and not the M4 tapped hole! sharrell

(posted 2013-05-01 09:03:00.0) Response from Sean at Thorlabs: Thank you for your feedback. Both the top and bottom plates of the DT12/M have tapped M4 holes. The stage can therefore be attached as shown, as you described using an SD1 adapter ring to fit an M4 cap screw through the counterbore of the RC1 and into the bottom tapped hole on the DT12/M. I'm going to add a caption to the photo to explain this today, and I'll add additional photos and text to clarify the mounting options over the next several days. lmorgus

(posted 2012-03-27 08:33:00.0) A response from Laurie at Thorlabs to the anonymous poster: Thank you for inquiring about our customer inspired notation. You are indeed correct that the DT Series of stages have been part of our product line for many years (since 2007). The customer inspired designation is attributed to the DT12B/M, which is our metric base plate. Although its imperial counterpart, the DT12B, has also been around since 2007 and was originally sold as a universal product (it had imperial 6-32 taps that could accept both imperial and M3 screws), the solution wasn't ideal. Based on a customer request to make a truly metric baseplate, the DT12B/M was put into production and given the customer-inspired designation. We now ship all our metric DT Series stages with this new customer-inspired base plate. user

(posted 2012-03-27 00:47:14.0) You said these are "customer inspired" but, come on now, I've had parts exactly like these in my lab for many years so they really can't be customer inspired, right. You might be able to snow the young guys but we old guys know the truth. bdada

(posted 2012-01-30 18:35:00.0) Response from Buki at Thorlabs:

The DT12/M has M4 mounting holes whereas the PH2/M has M6 so you cannot mount the PH2/M directly onto the DT12/M. Please consider using the AP6M4M adapter linked below and contact TechSupport@thorlabs.com if you have any questions:

http://www.thorlabs.com/NewGroupPage9.cfm?ObjectGroup_ID=1745&pn=AP6M4M jmcrespoc

(posted 2012-01-29 11:03:19.0) I want attach a PH2M post to this stage. Is this possible? jjurado

(posted 2011-03-31 11:58:00.0) Response from Javier at Thorlabs to Esteban Bermudez: Thank you very much for your feedback! You are correct, we should do a better job at specifying the screw sizes and hole dimensions of the DT12 series stages. To this end, we will modify the bill of materials of the DT12B base plate (included with the DT12XY/M) to include M3 attachment screws, and we will also add one M4 and one #8-32 countersunk screws for attaching the baseplate to the bottom of the stage. We will also update the drawings of these parts to make this information clearer. I will contact you directly in case you have any further questions. esteban.bermudez

(posted 2011-03-31 12:10:47.0) Hi,

I received my DT12XY/M today and realized something until I got it.

The description and drawings are not complete.

For example it´s never mentioned the type of screw required for the base plate, and eventhough the screws are included(which now I know its M3?) the screws are not fiting well to the holes(they don´t screw smoothly).

There should be a better description for this item.

Cheers,

Esteban jens

(posted 2009-05-27 12:16:50.0) A reply from Jens at Thorlabs: indeed this kind of miniature dovetail stage is offered by a few companies with very similar features. If you want to get a detailed comparison of spec values I will be happy to supply that based on any competitor item part number you are looking into. In a situation where the difference in the technical parameters is minor you also may want to take into account that we keep those items on stock for same day delivery. In addition we constantly add components to our portfolio to give you the highest possible flexibility in how to use and combine our items. So it might also be important to consider how the overall setup should look like and if you can get most or all those parts from one supplier which than will save you time and money. user

(posted 2009-05-27 01:17:54.0) Hey, I saw this exact same part from 2 other companys. Whats the difference? Why should I buy your instead of theirs. jmyrick

(posted 2007-12-04 05:19:50.0) There is nothing on this page that shows me what the function of the DT12XYZ-RA & DT12XYZ-RA/M, it would be great to see something that helps me to know what the part looks like. I also find the discription a little confusing what does "RA mounted" mean in the description? jmyrick

(posted 2007-12-04 04:20:23.0) Maybe a ghosted version of the cage rods showing the DT12CSA would help to make it more clear. I agree with ACable that the function is not obvious on the product page without having to go into the application tab. technicalmarketing

(posted 2007-11-19 14:50:44.0) To acable: Did you get a chance to look through the "Application Options" Tab? The DT12SCA is shown in a cage system, and the DT12RA is shown with a mounting base and lens mount. If these images are not helpful when it comes to addressing how these parts are used, please let us know. acable

(posted 2007-11-17 12:41:22.0) DT12SCA, it is not clear how this part is intended to be used, perhaps a photo with the unit placed in a cage system. It would also be nice if the distance from the top surface of the stage to the cage center line was included.

DT12RA, same here, the part by itself doesnt allow the reader to understand its application. |

Manual Linear Translation Stages

Thorlabs' manual translation stages are offered in a range of maximum travel distances, from less than 1/4" (6 mm) to 2" (50 mm) and longer for our long travel, large area platforms. Many of these stages can be ordered in multi-axis configurations, providing XY or XYZ translation. For fiber coupling applications, please see our Multi-Axis Stages, which offer finer adjustment than our standard manual translation stages. In addition to linear translation stages, we offer rotation stages, pitch and yaw platforms, and goniometers. We also offer motorized translation stages that are powered by DC Servo motors, stepper motors, or direct drive technology.

Crossed-Roller Bearing Stages

These linear translation stages feature crossed-roller bearing travel mechanisms for precision motion, high load capacity, and low angular deviation. The LNR Series stages feature all-steel body construction, while the LX, XRN, and XR Series stage bodies are constructed of cast tool and jig aluminum. We also offer several vertical crossed-roller bearing stages (see below).

| Crossed-Roller Bearing Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | LNR Series 25 mm Stages | LX Series 25 mm Stages |

XRN Series 25 mm Stages | XR Series 25 mm Stages | XR Series 50 mm Stages | LNR Series 50.8 mm Stages |

| Click Photo to Enlarge |

|

|

|

|

|

|

| Travel | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 25 mm (0.98") | 50 mm (1.97") | 50.8 mm (2") |

| Drive Type | Multiple | Micrometer | Micrometer | Micrometer | Micrometer | Multiple |

| Platform Size | 2.34" x 2.36" (59.4 mm x 60.0 mm) |

2.56" x 2.56" (65.0 mm x 65.0 mm) |

2.00" x 3.35" (50.7 mm x 85.0 mm) |

2.98" x 4.33" (75.7 mm x 110.0 mm) |

2.98" x 5.51" (75.7 mm x 140.0 mm) |

3.94" x 3.94" (100.0 mm x 100.0 mm) |

| Possible Axis Configurations |

X, XZ, XY, XYZ | X, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, Y, Z, XY, XZ, YZ, XYZ | X, XY, XYZ |

| Additional Details | ||||||

Ball Bearing Stages

These translation stages feature hardened steel linear bearings for precise motion and long life. They are available with a variety of actuators and in single-axis or preassembled multi-axis configurations.

| Ball Bearing Stages | |||||

|---|---|---|---|---|---|

| Product Family | MS Series 1/4" Stages | T12 Series 1/2" Stages | MT Series 1/2" Stages | PT Series 1" Stages | LT Series 2" Stages |

| Click Photo to Enlarge |  |

|

|

|

|

| Travel | 1/4" (6.4 mm) | 1/2" (12.7 mm) | 1/2" (12.7 mm) | 1" (25.4 mm) | 2" (50 mm) |

| Drive Type | Multiple | Thumbscrew | Multiple | Multiple | Differential Micrometer |

| Platform Size | 1.17" x 1.17" (29.7 mm x 29.7 mm) |

0.76" x 0.81" (19.3 mm x 20.6 mm) |

2.40" x 2.41" (61.0 mm x 61.2 mm) |

3.00" x 4.00" (76.2 mm x 101.6 mm) |

3.75" x 3.75" (95.3 mm x 95.3 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | |||||

Dovetail Stages

These compact stages incorporate dovetails and a leadscrew for the translation mechanism. They are suitable in general purpose motion control applications.

| Dovetail Stages | |||

|---|---|---|---|

| Product Family | DT Series 1/2" Stages | DTS Series 1" Stages (Vacuum-Compatible Version Available) |

DTS Series 2" Stage |

| Click Photo to Enlarge |  |

|

|

| Travel | 1/2" (12.7 mm) | 1" (25 mm) | 2" (50 mm) |

| Drive Type | Thumbscrew | Thumbscrew | Thumbscrew |

| Platform Size | 1.00" x 1.00" (25.4 mm x 25.4 mm) | 2.68" x 2.95" (68.0 mm 75.0 mm) | 2.68" x 3.74" (68.0 mm x 95.0 mm) |

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZa | X, XY, XYZ |

| Additional Details | |||

Flexure Stages

Thorlabs' Nanoflex™ translation stages feature frictionless flexure mechanisms for improved positioning and resolution when compared to similar stages made using bearings. The translation of the stage is accomplished by the elastic deformation (flexing) of a linkage attached to the mounting platform. Most models also include piezo actuators for small position adjustments.

| Flexure Stages | ||||

|---|---|---|---|---|

| Product Family | Nanoflex™ 1.5 mm Stage | Nanoflex™ 5 mm Stages | ||

| Click Photo to Enlarge |  |

|

|

|

| Travel | 1.5 mm (0.06") + 25 µm Piezo | 5 mm (0.20") | 5 mm (0.20") + 20 µm Piezo | |

| Drive Type | Thumbscrew and Piezo Actuator | Differential Micrometer | Differential Micrometer and Open-Loop Piezo Actuator |

Differential Micrometer and Closed-Loop Piezo Actuator |

| Platform Size | 1.18" x 1.18" (30.0 mm x 30.0 mm) | 2.95" x 2.95" (75.0 mm x 75.0 mm) | ||

| Possible Axis Configurations | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ | X, XY, XYZ |

| Additional Details | ||||

Vertical Stages

We offer vertical translation stages with crossed-roller bearings for precise motion as well as long travel vertical stages for heavy-duty applications.

| Vertical Stages | ||||||

|---|---|---|---|---|---|---|

| Product Family | XRN Series 9 mm Vertical Stage | XR Series 14 mm Vertical Stage | MVS Series 1/2" Vertical Stage | MVS Series 1" Vertical Stage | VAP Series 4" Vertical Stage | VAP Series 10" Vertical Stage |

| Click Photo to Enlarge |  |

|

|

|

|

|

| Travel | 9.0 mm (0.35") | 14.0 mm (0.55") | 1/2" (13.0 mm) | 1" (25.0 mm) | 4" (101.6 mm) | 10" (254 mm) |

| Drive Type | Worm-Gear Driven Lift Screw | Micrometer | Adjuster Knob and Coarse Manual Positioning | |||

| Platform Size | 2.00" x 2.00" (50.7 mm x 50.7 mm) |

2.98" x 2.98" (75.7 mm x 75.7 mm) |

2.36" x 2.36" (60.0 mm x 60.0 mm) | 3.00" x 6.00" (76.2 mm 152.4 mm) | ||

| Additional Details | ||||||

Click to Enlarge

DT12 Stage attached to a DT12B Base Plate (Not Included)

Click for Details

DT12(/M) Mechanical Drawing

- Single-Axis Dovetail Translation Stage

- Bottom-Located 8-32 (M4) Tap for Ø1/2" Post Compatibility

- Top-Located 8-32 (M4) Tap for Mounting Components

- Lockable Moving Platform

The DT12(/M) is a compact, 1/2" (12.7 mm) translation stage that incorporates a dovetail and lead screw translation mechanism for smooth linear positioning along the entire range of travel. The mounting platform is a 1.0" (25.4 mm) square that is translated using a precision M3 x 0.35 adjuster. The moving platform can be locked using a side-located setscrew and 0.05" hex key to guard against accidental movement. The top and bottom plates feature an 8-32 (M4) tap for a variety of mounting options. The maximum screw insertion depth for both of these taps is 9/64" (3.5 mm).

Multi-axis configurations using two or three DT12 stages are available below. However, two DT12 stages can be attached perpendicularly to one another using the DT12A Angle Bracket or DT12RA Rotation Adapter. XY configurations must be ordered preconfigured from Thorlabs in order to guarantee orthogonality.

Click to Enlarge

DT12XZ Translation Stage

- Preconfigured, 2-Axis XY and XZ Translators

- Bottom-Located 8-32 (M4) Tap for Ø1/2" Post Compatibility

- Top-Located 8-32 (M4) Tap for Mounting Components

- Each Stage Includes a DT12B(/M) Base Plate

- Lockable Axes of Translation

The DT12XY(/M) and DT12XZ(/M) are compact, two-axis translation stages that incorporate a dovetail and lead screw translation mechanism for smooth linear positioning along the entire range of travel for each axis. The DT12XY(/M) consists of two DT12(/M) stages, while the DT12XZ(/M) consists of two DT12(/M) stages and a DT12A Angle Bracket. Each stage also includes a base plate to mount it directly to an optical table. Please note that XY configurations must be ordered preconfigured from Thorlabs in order to guarantee orthogonality of the axes. The stages are permanently attached and cannot be separated.

Preconfigured 3-axis stages are available below.

Click to Enlarge

DT12A Angle Bracket Replaced with the DT12RA Rotation Adapter (Available Below)

- Preconfigured, 3-Axis XYZ Translator

- Bottom-Located 8-32 (M4) Tap for Ø1/2" Post Compatibility

- Top-Located 8-32 (M4) Tap for Mounting Components

- DT12B(/M) Base Plate Included

- Lockable Axes of Translation

The DT12XYZ(/M) is a compact, three-axis translation stage that incorporates a dovetail and lead screw translation mechanism for smooth linear positioning along the entire range of travel for each axis. It consists of a DT12XY(/M) 2-Axis Stage with a DT12(/M) stage attached using a DT12A Angle Bracket. The stage also includes a base plate to mount it directly to optical tables. Please note that the two stages forming the XY portion are permanently attached and cannot be separated.

Click to Enlarge A DT12 Stage with a DT12CTA Top Plate and CT101 Optic Mount

Click to Enlarge A DT12 Stage with a DT12CTA Top Plate and CT104 Rotation Mount

- Twelve 4-40 (M3) and Four 8-32 (M4) Tapped Mounting Holes for Increased Mounting Options

- Two 4 mm Wide Central Keyways for Aligning 30 mm Cage Stage Accessories

- Reference Lip Prevents Misalignments when Mounting the Plate

- Flatness: 0.05 mm (0.02")

- Parallelism: 0.05 mm (0.02")

The DT12CTA(/M) Top Plate features an array of tapped mounting holes with two 4 mm wide keyways to provide increased mounting options for our line of DT12 Dovetail Translation Stages. Two orthogonal keyways facilitate the mounting of 30 mm cage stage accessories, such as translation and rotation mounts for Ø1/2" optics or SM1-threaded (1.035"-40) mounts, as shown in the images to the right. When mounted, the optical axis will be 38.5 mm (1.51") from the base of the translation stage. The plate also contains twelve 4-40 (M3) and four 8-32 (M4) tapped mounting holes for securing and mounting various components. For complete dimensions and mounting hole locations, please see the mechanical drawings in the table to the right.

The top plate is attached to the DT12 dovetail stage via a central #8 (M4) counterbore and included 8-32 (M4) button-head screw. A lip that runs along a bottom edge of the plate creates a reference edge that prevents unwanted rotation of the plate when it is attached to the stage.

Click to Enlarge A DT12A Angle Bracket shown mounting two DT12 Stages perpendicular to one another. This XZ configuration is then mounted on a DT12B Base Plate.

- DT12A Angle Bracket Mounts Two DT12 Stages Perpendicular to One Another

- DT12B(/M) Baseplate Provides a Convenient Method of Bolting the Stage to an Optical Table

- CL6 Table Clamps Fix a DT12 Stage to an Optical Table

These mounting adapters provide simple methods of attaching multiple DT12 stages to one another or to an optical table or breadboard.

The DT12A Angle Bracket, which is compatible with both imperial and metric stages, allows two stages to be mounted perpendicular to each other. This bracket is required when assembling stages in an XZ, YZ, or XYZ configuration and is attached to the stages using the two supplied 8-32 (M4) countersunk screws.

The DT12B(/M) Base plate provides a convenient method of bolting the stage to the work surface. The base plate is first secured to the table with the included 1/4"-20 (M6) countersunk cap screw. The stage then fixes to the base plate using the supplied 6-32 (M3) bolts and cleats.

The CL6 table clamp offers an alternative method of fixing the stage to the work surface. Each stage includes mounting grooves along the top and bottom of the stage for direct attachment to an optical table using two clamps.

Click to Enlarge DT12RA Rotation Adapter and DT12 Stage Mounted on a DT12XY Stage

Click to Enlarge LMR1 Lens Mount Attached to a Rotation Adapter Without the Angle Bracket and Mounted on a

DT12B Base Plate

- Rotates any DT12 Stage or 8-32 (M4) Mounted Component up to 360º

- Mount Two DT12 Stages Perpendicular to One Another

- Flexure Clamp Locking Mechanism

The DT12RA(/M) rotation adapter enables any DT12 stage or 8-32 (M4) mounted component to be rotated up to 360o. The adapter includes an attached angle bracket which is easily mounted to an existing single, 2-axis, or 3-axis configuration using the included 8-32 (M4) countersunk screw, as shown in the photo to the right. Rotation is locked via a flexure clamp that is tightened using a side-located M3 cap screw and a 2.5 mm hex key. Please see the manual, which is available by clicking on the red Docs icon (![]() ) below, for complete mounting instructions.

) below, for complete mounting instructions.

The angle bracket can be removed, allowing the adapter to be used with the DT12CSA Cage System Adapter or secured directly to the work surface using the DT12B Base Plate or two CL6 Clamps. This is shown in the photo to the right, where an LMR1 Lens Mount is mounted on the rotation adapter, which is attached to a DT12B base.

Click to Enlarge DT12CSA and DT12XY Stage Mounted on Two Ø6.0 mm cage rods

Click to Enlarge

DT12 Stage Mounted on the DT12CSA 60 mm Cage Adapter

- Mount DT12 Stages and DT12RA Rotation Adapters Within a 60 mm Cage System

- Allows for Coarse Adjustment Along Cage Rods

- Can be Locked onto Cage Rods with Two Side-Located M3 Nylon-Tipped Setscrews

The DT12CSA 60 mm Cage System Adapter allows a DT12 Translation Stage or DT12RA Rotation Adapter to be mounted over two Ø6.0 mm cage rods, as shown in the photo to the far right. The adapter provides coarse translation along the length of the cage system and can be locked in place with two M3 nylon-tipped setscrews and a 1.5 mm hex key.

A DT12(/M) stage is mounted using 8-32 (M4) countersunk screws, as shown in the photo to the right, whereas the DT12RA(/M) rotation adapter is attached using the M4 cap screws. All mounting screws are included with the DT12CSA. Please note that the angle bracket included with the DT12RA must be detached from the rotation adapter before it can be attached to the DT12CSA 60 mm cage adapter.

When inserted into a 60 mm cage system with a DT12 stage or DT12RA adapter attached, the distance from the top surface of the attached accessory to the center line of the cage system will be about 23.2 mm (0.91") for the DT12 stage and 29.5 mm (1.16") for the DT12RA rotation adapter.

Products Home

Products Home

Zoom

Zoom

Mini-Stage, Dovetail Mechanism

Mini-Stage, Dovetail Mechanism