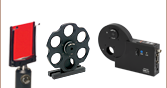

Motorized Fast-Change Filter Wheel

- 55 ms Filter Change Time with Included Controller

- Light-tight Design

- Cage and Lens Tube Compatible

FW103H

Motorized Filter Wheel

(BSC201 Controller Included)

BSC201

High-Speed Switching Controller

Application Idea

Compatible with Our Ø1/2" Posts,

30 mm Cage System, and

SM1 Lens Tube Components

Please Wait

| Motorized Filter Wheel Selection Guide | ||||

|---|---|---|---|---|

| Item # | # of Slots | Filter Size | Preloaded ND Filters | Features |

| FW212C | 12 | Ø1/2" | No | BNC, RS-232 and USB Interfaces Integrated Controller |

| FW212CNEB | 12 | Ø1/2" | Yes | |

| FW102C | 6 | Ø1" | No | |

| FW102CNEB | 6 | Ø1" | Yes | |

| FW103H | 6 | Ø1" | No | 55 ms Switching Time |

Features

- Change Time of 55 - 60 ms When Used with Included BSC201 Controller

- Holds up to Six Ø1" (Ø25 mm) Filters

- Accepts Filters up to 0.25" (6.35 mm) Thick

- Light-Tight Design

- Filters Easily Added or Removed

- Compatible with All APT™ Stepper Motor Controllers

This motorized fast-change filter wheel has been designed for applications that require sequential observations with different filters inserted in the optical path, such as multi-wavelength fluorescence imaging. The optical port is internally SM1 (1.035"-40) threaded on both sides for compatibility with our Ø1" lens tubes, and each side contains four 4-40 taps for compatibility with our 30 mm cage systems. The perimeter of the housing contains four 8-32 (M4) tapped holes at 90° spacings to allow the wheel to be mounted on Ø1/2" posts. Up to six Ø1" (Ø25.4 mm) filters mounted in the standard housing (e.g., Thorlabs' FELH series) can be fitted onto the wheel. A removable cover allows filters to be installed without needing to unmount the filter wheel from the optomechanical setup within which it sits.

The FW103H(/M) includes the filter wheel and our BSC201 Single-Channel APT™ Controller, which provides a switching time between 55 - 60 ms for adjacent filters. The BSC201 comes with a power supply for 110 to 240 V and with a US, UK, or European power cord determined by your ordering location. The filter wheel can also be used with the KST201 K-Cube™ controller, but the switching time will increase to 250 ms. If you are interested in this option, please contact Technical Support to inquire about purchasing a filter wheel without the BSC201 controller.

The filter wheel uses a Hall effect sensor to determine the filter wheel's position, which is ideal for light-sensitive applications.

The Motorized Fast-Change Filter Wheel can hold up to six Ø1" filters, which can be easily inserted into the wheel in three steps.

Step 1

Click to Enlarge

Remove the housing cover to gain access to the six filter slots (individual filters can be changed by using the filter access cover located on the housing cover, shown to the bottom left)

Step 2

Click to Enlarge

Insert the filter into the desired port of the filter wheel

Step 3

Click to Enlarge

Secure the filter's position using one of the provided retaining rings and three screws as shown above. Use M2 x 8 for filters 6.0 - 6.3 mm thick and correspondingly shorter screws for thinner filters.

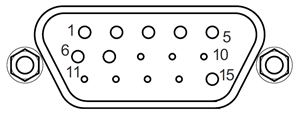

Motor Connector

D-type Male

| Pin | Description | Pin | Description | Pin | Description |

|---|---|---|---|---|---|

| 1 | Limit Switch Ground | 6 | Phase A -ve | 11 | Not Connected |

| 2 | Not Connected | 7 | Phase A +ve | 12 | Not Connected |

| 3 | C/W Limit Switch | 8 | Not Connected | 13 | + 5 V DC |

| 4 | Phase B -ve | 9 | Not Connected | 14 | Not Connected |

| 5 | Phase B +ve | 10 | + 5 V DC | 15 | Ground/Earth |

| Posted Comments: | |

hai YUAN

(posted 2024-01-19 10:02:56.927) 请提供一下滤光转轮的产品规格,比如重复定位精度 hchow

(posted 2024-02-06 04:08:24.0) FW103H 电动过滤轮配有步进电机,其最小步进角为 1.8º,步进精度为 5%。我们没有直接提供重新定位精度的规格。重新定位精度取决于重新定位的方式。虽然我们没有直接提供这一规格,但如果您需要一个近似值,它大约是步进精度值的两倍。 hchow

(posted 2024-02-06 04:08:24.0) FW103H 电动过滤轮配有步进电机,其最小步进角为 1.8º,步进精度为 5%。我们没有直接提供重新定位精度的规格。重新定位精度取决于重新定位的方式。虽然我们没有直接提供这一规格,但如果您需要一个近似值,它大约是步进精度值的两倍。 Bartek Waclaw

(posted 2023-10-31 15:40:16.31) Has there been any development regarding a driver for MicroManager? The last relevant post is from 2011. GBoedecker

(posted 2023-11-09 09:51:45.0) Thank you for your feedback! We are currently developing new device adapters for MicroManager. I will contact you directly to keep you up to date. Ting He

(posted 2022-12-19 20:49:30.963) The wheels lost its position with 6 filters assembled. However, it works well with 5 or less filters. It seems not an accident because it happends in another FW103H/BSC203 as a test.

What shall I do? JReeder

(posted 2023-01-05 10:38:25.0) Thank you for your enquiry. I reached out to you directly in order to troubleshoot this issue. pranav rathi

(posted 2019-11-25 23:20:45.66) Product is good but the I have seen that Thorlabs controllers are very bulky, make the controllers compact and beautiful like PI controllers. AManickavasagam

(posted 2019-12-03 11:28:26.0) Thank you for your feedback. I will pass this on to our Engineering team. peter.dedecker

(posted 2016-11-18 08:23:57.993) We have generally good experiences with Thorlabs hardware, but the FW103H/BSC-1 is a flawed product and we have not been able to use it to specifications.

1. The APT software would crash on startup, making it impossible to use the device. Thorlabs support was uncommunicative in fixing this issue until we called on a friend who works at Thorlabs Sweden (support id ##257058##). The fix was to reflash the firmware and to download an older version of APT.

2. The communication over RS-232 doesn't work properly - we receive no 'filter moved' response from the device, which means that we can never be sure when the move has completed.

3. Thorlabs support has generally been unhelpful and they have stopped responding to our requests for help with the communication issue (support id ##264349##, communication with M.S.).

4. Filter mounting system doesn't work well.

Given the lack of support and the issues encountered, I strongly caution against buying this device. We will look into returning this device and buying a competitor's offering instead. bhallewell

(posted 2016-11-22 11:50:39.0) Response from Ben at Thorlabs: Please let me first apologise on behalf of our UK Tech support effort for the experience you have faced so far. It is clear that you've experienced a number of problems in operating our FW103H/M hardware bundle through our APT freeware & low-level communications protocol. It is also extremely regrettable to hear that you feel that you have not received the support you require within your setup. We pride ourselves on the quality of customer service that we continually work to provide on a daily basis & we can only continue to improve the delivery of our service.

Please note that I have picked up the details of your query & have sent you over some details on rules for using the low-level communication protocol with the FW103H specifically. In general & for future reference it is good practise to refer to the Output Window within Kinesis or the System Log within APTUser to track exchanges between the controller & filter wheel, should you wish to control the device through your own VCP application. allanfontes

(posted 2013-05-02 14:31:52.04) Thanks for this oportunity.

I m looking for a filter wheel with following specifications:

-Six fiter slots;

-55,5 ms time change between filters;

-Possibility of control to obtain phase lock with frame capture;

-Control by USB, if possible;

I d like a sugestion of a product with these especifications.

The FW103H/M looks like what I m loking for.

Any information will be useful.

Allan Fontes cdaly

(posted 2013-05-09 10:34:00.0) Response from Chris at Thorlabs: Thak you for using our web feedback. The FW103/M will be able to have a 55-60ms time change between filters if it is used with the BSC201 controller. It would be slower (~250ms) using the TST001. With the BSC201 there is the trigger out function which will send a trigger for every move if necessary, this signal could then be used to synchronize with other devices. sharrell

(posted 2012-01-06 10:42:00.0) Reply from Sean at Thorlabs: Thank you for your feedback regarding a step file. I have sent you a step file, which shows the filter wheel with cover removed, directy. user

(posted 2011-11-28 21:35:04.0) A response from Tyler at Thorlabs: This is in response to the micro-manager discussion. Javier was mistaken when he posted about the availability of a micro-manager interface to the FW103 controller. Although we did comunicate with a previous customer who was working on developing their own micro-manager solution, this communication did not result in the creation of a micro-manager solution. I am sorry for the confusion that we created. htowns1

(posted 2011-11-21 17:02:21.0) I could not find a step model with the filter shroud removed. I have a application that is space limited and requires the filter shroud off. if you have a model without the shroud it would helpful. bdada

(posted 2011-11-10 18:50:00.0) Response from Buki at Thorlabs:

Thank you for your feedback. I apologize for the inconsistent information. I am looking into this further and will post a more complete response shortly. user

(posted 2011-11-09 16:58:44.0) Dear Buki: I am confused. Javier responded to philip.cheney of 2011-06-28 saying Thorlabs has developed a micromanager adapter for the BSC101 controller. At least that is what philip.cheney was asking for in his request of 2011-06-23 where he asked for a Micro-manager software adapter to run the BSC101. The BSC101 controller is what runs the FW103 in the FW103H package, and is not used to run the FW102, so when I ask for FW103 Micro-manager support, I am asking the same question as philip.cheney. I would purchase the FW103 with BSC101 = FW103H if a Micro-manager software adapter is available. Could you please double-check with Javier about whether such a software adapter truly exists? Thank you. bdada

(posted 2011-11-09 16:08:00.0) Response from Buki at Thorlabs:

Thank you for using our Feedback Forum. The Micro-manager adapter and documentation we have is for the FW102. At this time we do not have the same information for the FW103 or FW103H. Please contact TechSupport@thorlabs.com if you have additional questions. mzlin

(posted 2011-11-08 16:29:09.0) Could you please also email me the Micro-manager adapter and documention that will drive the FW103H? We will also need this in order to use the FW103 system. I believe you have my email address via the webform. Thank you! jjurado

(posted 2011-06-28 17:52:00.0) Response from Javier at Thorlabs to philip.cheney: Thank you very much for contacting us. We have developed a micromanager adapter and documentation based on one of our APT-driven XY stages that will also apply to the filter wheel. I will contact you directly with this information. philip.cheney

(posted 2011-06-23 14:16:04.0) As poster pattersg mentioned, a MicroManager adapter would be extremely helpful. You mentioned plans to develop such an adapter. Has any progress been made? Im using the BSC101 controller. Customer Email: philip.cheney@du.edu This customer would like to be contacted. tor

(posted 2011-01-10 16:40:55.0) Response from Tor at Thorlabs to adavid: Thank you for your feedback. I will contact you to identify a solution for making this compatible with your microscope. adavid

(posted 2010-12-16 18:15:55.0) Hi, the wheel is very fast and has a low profile overall, which is nice. However:

- the motor comes very close to the aperture, and therefore leaves little clearance. I found it impossible to mount a (small) CCD right at the output of the wheel (eg I have to use some extension tube). This is a problem when installing the wheel at the output port of a microscope, because the CCD can not be in the image plane (parfocality with the eyepiece is lost)

- also: when using the APT software with default settings, it seems that the speed/acceleration is too fast so that the wheel loses its position (after a few back and forth movements it stops in-between two filters). I had to slow down speed/accel to get proper positioning. Not a huge issue, but if this happens to others it should be documented. user

(posted 2010-09-27 04:54:01.0) A Reply from Oli at Thorlabs to Hyoon: The FW103 filter wheel uses Magnetic hall affect sensors to determine position. hyoon

(posted 2010-09-23 14:25:57.0) How are the filter positions determined? Are they sensed using magnetic hall effect sensors or sensed using LEDs and photodiodes? I would like to use the filter wheels in a light sensitive environment where the additional source of radiation would be problematic. Thorlabs

(posted 2010-08-18 10:31:26.0) Response from Javier at Thorlabs to pattersg: Thank you for your feedback. The new FW102C filter wheel will have the same communication interface as the FW102B, so the Micromanager adapter will work for it, as well. Regarding the FW103H filter wheel, we do not have the necessary drivers for uManager. However, it is in our plans to develop them within the next few months. I will keep you updated of the status. pattersg

(posted 2010-08-17 13:33:20.0) I am controlling my instrument with Micromanager and we generally need an adapter for each new device we add. An adapter for the FW102B and FW212B has been written (http://valelab.ucsf.edu/~nico/MMwiki/index.php/Thorlabs_FilterWheel), but it seems these are no longer offered. Is the communication with the FW102C the same as with the FW102B? Or similar enough that the adapter will work?

Also, Im interested in the FW103H with the BSC101 controller, but Im hesitant to install it in my system without the capability of Micromanager control. Writing these adapters is currently beyond my meager coding skills. Would you consider developing an adapter for the FW103H or updating the adapter for the FW102C if necessary?

Thanks. Adam

(posted 2010-04-27 17:19:38.0) A response from Adam at Thorlabs to runcyclexcski: We currently do not have this specification. We will test the repeatability and post data on the web early next week. I will contact you directly to find out if you need more information. runcyclexcski

(posted 2010-04-24 01:16:22.0) Please contact me ASAP with the specs on flip to flip repeatability for this filter wheel. apalmentieri

(posted 2010-03-01 09:44:05.0) A response from Adam at Thorlabs to vincent: We can provide an increase in the length of the cable as a custom option. I will contact you directly to find out how long the cable needs to be for your application. vincent.daria

(posted 2010-02-28 23:40:41.0) Connector wire from filter wheel (FW103) to controller (TST001) is too short and the extension cable (PAA632) doesnt work with it. There is no option to increase the cable length! klee

(posted 2009-10-21 17:08:14.0) A response from Ken at Thorlabs to bramvdbroek: Thank you for your feedback and I apologize for the inconvenience you had in mounting the filters in the FW103. We are actually working on a new design that will have significant improvements in speed and mounting. We will send you a free unit for evaluation when it is complete. bramvdbroek

(posted 2009-10-21 14:36:58.0) Dear Thorlabs,

I like the speed of your FW103 filter wheel, but the way in which the filters are to be mounted is absolutely horrible!

It is at best reasonable for standard Thorlabs mounted filters, but for any other filter with a different thickness the 8 mm screws to fit them are too long. I have just spent over an hour trying to put in an unmounted filter without damaging it by sliding screws and/or retaining ring. And then it says on the website "filters easily added or removed"!

How about designing a way to first mount the filters into some holder outside of the filterwheel, and click that assembly into the wheel.

Best regards,

Bram van den Broek

Leiden Institute of Physics |

Products Home

Products Home

Fast Change Filter Wheel

Fast Change Filter Wheel