Fixed Lens Mounts for OEM Applications

- Fixed Mounts for Ø1/2", Ø1", or Ø2" Optics

- Matching Optic Axis Height for OEM Applications

- Baseplates Available for Breadboard Compatibility

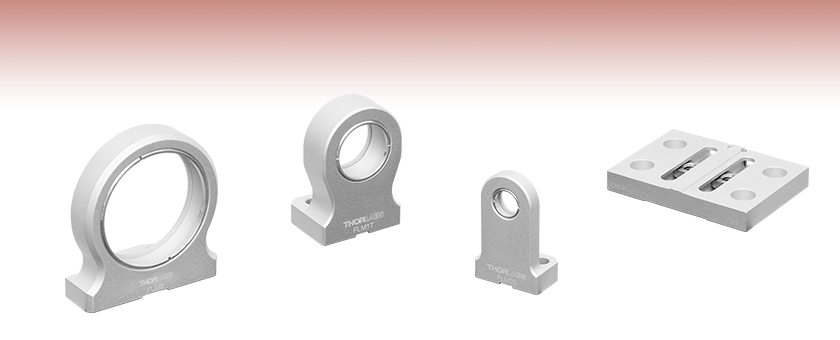

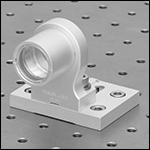

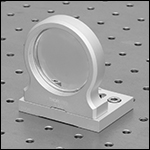

FLM2

Ø2" Fixed Lens Mount,

0.36" Max Optic Thickness

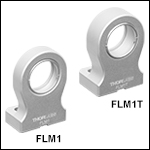

FLM1T

Ø1" Fixed Lens Mount,

0.48" Max Optic Thickness

FLM05

Ø1/2" Fixed Lens Mount,

0.14" Max Optic Thickness

FMB2

Translation Baseplate

Please Wait

| Table 1.1 Vacuum Specifications | |

|---|---|

| Vacuum Compatibility as Packageda |

>10-6 Torr |

| Materials | 6061-T6 Aluminum |

| Preparation and Packaging |

Chemically Cleaned and Double Vacuum-Bagged |

Mounts for OEMs

Thorlabs' Fixed Lens Mounts were designed to meet the needs of OEM customers. To that end, we are equipped to manufacture these mounts in high volumes and with timed delivery. Additionally, we can design and manufacture modified versions of these mounts for mounting additional optic types, sizes, and shapes. For example, we have produced similar fixed mounts for square mirrors, diffraction gratings, different optic sizes, or different beam heights. To find out more about our OEM capabilities, please contact Tech Sales.

Features

- Fixed Lens Mounts for Ø1/2", Ø1", or Ø2" Optics

- Available for Standard or Thick Optics

- Internally SM-Threaded

- Suitable for Vacuum Applications

- Common Optical Axis Height of 1.50"

- Mounting Holes for Use with 1/4" (M6) Screws

- Breadboard Compatibility via Translation or Rotation Baseplates

Thorlabs' Fixed Optic Mounts for OEM Applications are designed to support a seamless transition from benchtop R&D to high-volume OEM laser system production. All mounts share a unified optical axis height, providing beam path consistency and interchangeability to help simplify prototype layout and production integration. Separate baseplates provide breadboard compatibility for prototyping flexibility and integration into full optical systems during the development phase. The fixed optic height and mechanical footprint allow for direct transfer of mounts into the proven system, with a cavity-ready form factor supporting direct mounting into custom laser system substructures. This overall architecture enables OEM designers to rapidly develop and iterate optical systems on standard breadboards, then deploy those exact assemblies in production environments with no change in alignment geometry, reducing validation requirements and increasing long-term system reliability.

For applications where kinematic adjustment is not needed, these internally SM-threaded fixed lens mounts offer a simple way to mount lenses and other optical components. They feature a built-in mounting flange and maintain a common mounting height across all sizes, making them ideal for OEM applications. Each mount is fabricated from unanodized 6061-T6 aluminum and double vacuum-bagged, making them suitable for cleanroom and vacuum chamber environments; vacuum specifications are provided in Table 1.1. As shown in Figure 1.2, these mounts share the same optical height as our fixed mirror mounts making them well-suited for OEM integration.

Fixed Lens Mounts for OEM Applications (FLM Series)

Thorlabs’ FLM Series of fixed lens mounts are available for Ø1/2", Ø1", and Ø2" optics. Each mount includes a retaining ring to secure the optic against the rear lip of the mount; see the Threading Specs tab to learn more about SM threading. Alternatively, the SM-threaded bore allows a variety of threaded optical components to be directly attached. Two through holes on the mounting flange accept 1/4" (M6) cap screws for mounting, including one tight-fit clearance hole for use with a shoulder screw to aid in repeatable positioning. Each optic size mount is offered in both standard and extra-thick versions, the latter designed to support thicker optics.

Baseplates for OEM Fixed Optic Mounts

To ensure compatibility with standard breadboards or optical tables, baseplates are available separately. Options include manual translation baseplates, which provide up to 1.5" (31.8 mm) of linear mount travel, and rotation baseplates, which offer up to 90° of rotational adjustment.

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

| Posted Comments: | |

| No Comments Posted |

- Constructed from Unanodized Aluminum for Vacuum Applications

- Internally SM05-Threaded for Ø1/2" (Ø12.7 mm) Optics

- Common Optical Axis Height Ideal for OEM Applications

- Available for Standard or Thick Optics

- Built-In Mounting Flange for 1/4" (M6) Screws

These fixed optic mounts provide a simple solution for mounting lenses and other optical components. Each mount features an

For compatibility with breadboards and optical tables, please see Table G1.2 for recommended baseplates available separately below.

| Table G1.2 Specifications | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Optic Size | Clear Aperturea | Max Optic Thickness | Optical Axis Height | Included Retaining Ring | Suggested Spanner Wrench | Suggested Spanner Bit | Baseplate Compatibility |

| FLM05(/M) | Ø1/2" (Ø12.7 mm) | Ø0.44" (Ø11.0 mm) | 0.14" (3.6 mm) | 1.50" (38.1 mm) | SM05RRV | SPW603, SPW603L, or SPW801 | SPB05 | FMB2(/M) or FMB1(/M) |

| FLM05T(/M) | 0.28" (7.1 mm) | |||||||

- Constructed from Unanodized Aluminum for Vacuum Applications

- Internally SM1-Threaded for Ø1" (Ø25.4 mm) Optics

- Common Optical Axis Height Ideal for OEM Applications

- Available for Standard or Thick Optics

- Built-In Mounting Flange for 1/4" (M6) Screws

These fixed optic mounts provide a simple solution for mounting lenses and other optical components. Each mount features an SM1-threaded (1.035"-40) bore for mounting Ø1" optics and other optical components. These mounts are offered in both a standard (Item # FLM1(/M)) and thick version

For compatibility with breadboards and optical tables, please see Table G2.3 for recommended baseplates available separately below.

| Table G2.3 Specifications | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Optic Size | Clear Aperturea | Max Optic Thickness | Optical Axis Height | Included Retaining Ring | Suggested Spanner Wrench | Suggested Spanner Bit | Baseplate Compatibility |

| FLM1(/M) | Ø1" (Ø25.4 mm) | Ø0.90" (Ø22.9 mm) | 0.28" (7.1 mm) | 1.50" (38.1 mm) | SM1RRV | SPW606, SPW602, or SPW801 | SPB1 | FMB2(/M) or FMB1(/M) |

| FLM1T(/M) | 0.48" (12.1 mm) | |||||||

- Constructed from Unanodized Aluminum for Vacuum Applications

- Internally SM2-Threaded for Ø2" (Ø50.8 mm) Optics

- Common Optical Axis Height Ideal for OEM Applications

- Available for Standard or Thick Optics

- Built-In Mounting Flange for 1/4" (M6) Screws

These fixed optic mounts provide a simple solution for mounting lenses and other optical components. Each mount features an

For compatibility with breadboards and optical tables, please see Table G3.2 for recommended baseplates available separately below.

| Table G3.2 Specifications | ||||||||

|---|---|---|---|---|---|---|---|---|

| Item # | Optic Size | Clear Aperturea | Max Optic Thickness | Optical Axis Height | Included Retaining Ring | Suggested Spanner Wrench | Suggested Spanner Bit | Baseplate Compatibility |

| FLM2(/M) | Ø2" (Ø50.8 mm) | Ø1.90" (Ø48.3 mm) | 0.36" (9.1 mm) | 1.50" (38.1 mm) |

SM2RRV | SPW604 or SPW801 | SPB2 | FMB3(/M) or FMB1(/M) |

| FLM2T(/M) | 0.52" (13.1 mm) | |||||||

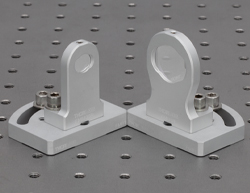

- Attach OEM Fixed Optical Mounts via 1/4"-20 (M6 x 1.0) Square Nut

- Mount on Breadboard or Optical Table via Clearance Hole for 1/4" (M6) Cap Screws

- Translation Slot Provides Up to 1.25" (31.8 mm) Linear Translation

These baseplates provide compatibility between OEM fixed optic mounts and standard breadboards or optical tables. Each baseplate includes four counterbored mounting holes for 1/4" (M6) cap screws to secure it to the optical table. Optic mounts are attached using two 1/4"-20 (M6 x 1.0) square nuts inserted into the translation clearance slots on the baseplate. This configuration allows the mounts to be translated by up to 1.25" (31.8 mm) while the baseplate remains stationary, as shown in Figure 803A.

The FMB2(/M) translation baseplate is compatible with OEM fixed optic mounts designed for Ø1/2" (Ø12.7 mm) and Ø1" (Ø25.4 mm) optics. The FMB3(/M) translation baseplate is compatible with mounts designed for Ø1.5" (Ø38.1 mm) and Ø2" (Ø50.8 mm) optics.

Click to Enlarge

Figure 788A Two Rear-Loading Mirror Mounts with Dichroic Mirrors Mounted on FMB1 Baseplates

- Attach OEM Fixed Optic Mounts via 1/4"-20 (M6 x 1.0) Tapped Holes

- Included Dowel Pin Adapter Provides Pivot Point for Rotation

- Mount on Breadboard or Optical Table via Clearance Slot for 1/4" (M6) Cap Screws

- Clearance Slot Provides Up to 90° Rotation

The FMB1(/M) Rotation Baseplate provides compatibility between the OEM fixed optic mounts and standard breadboards or optical tables. Four 1/4"-20 (M6 x 1.0) tapped holes through the baseplate match the footprint of all sizes of the OEM fixed optic mounts. An included dowel pin adapter is threaded into the central 1/4"-20 (M6 x 1.0) tap, providing a pivot point about which the baseplate can rotate when placed in one of the holes of a breadboard or optical table. A curved clearance slot allows the baseplate to be secured to a breadboard or optical table and provides up to 90° of rotation without removing the mounting cap screw.

Products Home

Products Home

Zoom

Zoom

Fixed Lens Mounts for OEM Applications

Fixed Lens Mounts for OEM Applications