Photosensitive Single Mode Fiber

- Enhanced Photosensitivity

- Low Loss Photosensitive Fibers

- Cladding Mode Suppressed Photosensitive Fibers

- Select Cut-Off Photosensitive Fibers

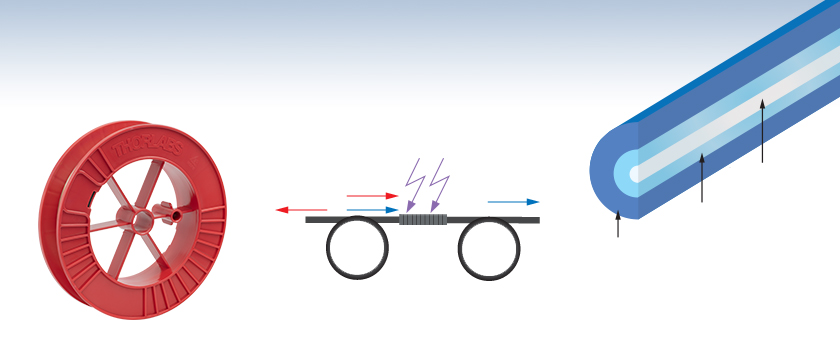

Photosensitive Single Mode

Fiber Cross Section

(Not to

Scale)

Dual Acrylate

Coating

Cladding

Doped Silica

Core

Application Idea

UV lasers can be used to "write" a fiber Bragg grating on photosensitive fibers.

GF1

1500 - 1600 nm,

10.5 µm MFD

Please Wait

Photosensitive Single Mode Fiber

Thorlabs offers a range of photosensitive single mode fibers designed to provide high photosensitivity for UV radiation. These fibers offer low splice loss to transmission fiber and are suitable for a range of applications, including writing a fiber Bragg grating onto the fiber for communications systems. Please see the table below for specifications regarding each product. We recommend T06S13 for use as a stripper tool when removing the buffer from these optical fibers in preparation for connectorization.

| Item # | Type | Operating Wavelength | Mode Field Diameter | Cut-Off Wavelength |

|---|---|---|---|---|

| GF1 | Standard | 1500 - 1600 nm | 9.3 ± 0.5 µm at 1310 nm 10.5 ± 1.0 µm at 1550 nm |

1260 ± 75 nm |

| GF3 | Standard | 1500 - 1600 nm | 7.5 ± 0.5 µm at 1550 nm | 1350 ± 50 nm |

| GF1B | Low Loss | 1500 - 1600 nm | 10.4 ± 0.8 µm at 1550 nm | 1260 ± 100 nm |

| GF4A | Cladding Mode Offset | 1500 - 1600 nm | 4.0 ± 0.3 µm at 1550 nm | 1350 ± 100 nm |

| PS1060 | Select Cut-Off | 980 - 1060 nm | 6.2 ± 0.8 µm at 1060 nm | 920 ± 50 nm |

| PS-PM980 | Polarization Maintaining | 970 - 1550 nm | 6.6 ± 1.0 µm at 980 nm | 900 ± 70 nm |

| Quick Links |

|---|

| Damage at the Air / Glass Interface |

| Intrinsic Damage Threshold |

| Preparation and Handling of Optical Fibers |

Laser-Induced Damage in Silica Optical Fibers

The following tutorial details damage mechanisms relevant to unterminated (bare) fiber, terminated optical fiber, and other fiber components from laser light sources. These mechanisms include damage that occurs at the air / glass interface (when free-space coupling or when using connectors) and in the optical fiber itself. A fiber component, such as a bare fiber, patch cable, or fused coupler, may have multiple potential avenues for damage (e.g., connectors, fiber end faces, and the device itself). The maximum power that a fiber can handle will always be limited by the lowest limit of any of these damage mechanisms.

While the damage threshold can be estimated using scaling relations and general rules, absolute damage thresholds in optical fibers are very application dependent and user specific. Users can use this guide to estimate a safe power level that minimizes the risk of damage. Following all appropriate preparation and handling guidelines, users should be able to operate a fiber component up to the specified maximum power level; if no maximum is specified for a component, users should abide by the "practical safe level" described below for safe operation of the component. Factors that can reduce power handling and cause damage to a fiber component include, but are not limited to, misalignment during fiber coupling, contamination of the fiber end face, or imperfections in the fiber itself. For further discussion about an optical fiber’s power handling abilities for a specific application, please contact Thorlabs’ Tech Support.

Click to Enlarge

Undamaged Fiber End

Click to Enlarge

Damaged Fiber End

Damage at the Air / Glass Interface

There are several potential damage mechanisms that can occur at the air / glass interface. Light is incident on this interface when free-space coupling or when two fibers are mated using optical connectors. High-intensity light can damage the end face leading to reduced power handling and permanent damage to the fiber. For fibers terminated with optical connectors where the connectors are fixed to the fiber ends using epoxy, the heat generated by high-intensity light can burn the epoxy and leave residues on the fiber facet directly in the beam path.

| Estimated Optical Power Densities on Air / Glass Interfacea | ||

|---|---|---|

| Type | Theoretical Damage Thresholdb | Practical Safe Levelc |

| CW (Average Power) |

~1 MW/cm2 | ~250 kW/cm2 |

| 10 ns Pulsed (Peak Power) |

~5 GW/cm2 | ~1 GW/cm2 |

Damage Mechanisms on the Bare Fiber End Face

Damage mechanisms on a fiber end face can be modeled similarly to bulk optics, and industry-standard damage thresholds for UV Fused Silica substrates can be applied to silica-based fiber. However, unlike bulk optics, the relevant surface areas and beam diameters involved at the air / glass interface of an optical fiber are very small, particularly for coupling into single mode (SM) fiber. therefore, for a given power density, the power incident on the fiber needs to be lower for a smaller beam diameter.

The table to the right lists two thresholds for optical power densities: a theoretical damage threshold and a "practical safe level". In general, the theoretical damage threshold represents the estimated maximum power density that can be incident on the fiber end face without risking damage with very good fiber end face and coupling conditions. The "practical safe level" power density represents minimal risk of fiber damage. Operating a fiber or component beyond the practical safe level is possible, but users must follow the appropriate handling instructions and verify performance at low powers prior to use.

Calculating the Effective Area for Single Mode Fibers

The effective area for single mode (SM) fiber is defined by the mode field diameter (MFD), which is the cross-sectional area through which light propagates in the fiber; this area includes the fiber core and also a portion of the cladding. To achieve good efficiency when coupling into a single mode fiber, the diameter of the input beam must match the MFD of the fiber.

As an example, SM400 single mode fiber has a mode field diameter (MFD) of ~Ø3 µm operating at 400 nm, while the MFD for SMF-28 Ultra single mode fiber operating at 1550 nm is Ø10.5 µm. The effective area for these fibers can be calculated as follows:

SM400 Fiber: Area = Pi x (MFD/2)2 = Pi x (1.5 µm)2 = 7.07 µm2 = 7.07 x 10-8 cm2

SMF-28 Ultra Fiber: Area = Pi x (MFD/2)2 = Pi x (5.25 µm)2 = 86.6 µm2 = 8.66 x 10-7 cm2

To estimate the power level that a fiber facet can handle, the power density is multiplied by the effective area. Please note that this calculation assumes a uniform intensity profile, but most laser beams exhibit a Gaussian-like shape within single mode fiber, resulting in a higher power density at the center of the beam compared to the edges. Therefore, these calculations will slightly overestimate the power corresponding to the damage threshold or the practical safe level. Using the estimated power densities assuming a CW light source, we can determine the corresponding power levels as:

SM400 Fiber: 7.07 x 10-8 cm2 x 1 MW/cm2 = 7.1 x 10-8 MW = 71 mW (Theoretical Damage Threshold)

7.07 x 10-8 cm2 x 250 kW/cm2 = 1.8 x 10-5 kW = 18 mW (Practical Safe Level)

SMF-28 Ultra Fiber: 8.66 x 10-7 cm2 x 1 MW/cm2 = 8.7 x 10-7 MW = 870 mW (Theoretical Damage Threshold)

8.66 x 10-7 cm2 x 250 kW/cm2 = 2.1 x 10-4 kW = 210 mW (Practical Safe Level)

Effective Area of Multimode Fibers

The effective area of a multimode (MM) fiber is defined by the core diameter, which is typically far larger than the MFD of an SM fiber. For optimal coupling, Thorlabs recommends focusing a beam to a spot roughly 70 - 80% of the core diameter. The larger effective area of MM fibers lowers the power density on the fiber end face, allowing higher optical powers (typically on the order of kilowatts) to be coupled into multimode fiber without damage.

Damage Mechanisms Related to Ferrule / Connector Termination

Click to Enlarge

Click to EnlargePlot showing approximate input power that can be incident on a single mode silica optical fiber with a termination. Each line shows the estimated power level due to a specific damage mechanism. The maximum power handling is limited by the lowest power level from all relevant damage mechanisms (indicated by a solid line).

Fibers terminated with optical connectors have additional power handling considerations. Fiber is typically terminated using epoxy to bond the fiber to a ceramic or steel ferrule. When light is coupled into the fiber through a connector, light that does not enter the core and propagate down the fiber is scattered into the outer layers of the fiber, into the ferrule, and the epoxy used to hold the fiber in the ferrule. If the light is intense enough, it can burn the epoxy, causing it to vaporize and deposit a residue on the face of the connector. This results in localized absorption sites on the fiber end face that reduce coupling efficiency and increase scattering, causing further damage.

For several reasons, epoxy-related damage is dependent on the wavelength. In general, light scatters more strongly at short wavelengths than at longer wavelengths. Misalignment when coupling is also more likely due to the small MFD of short-wavelength SM fiber that also produces more scattered light.

To minimize the risk of burning the epoxy, fiber connectors can be constructed to have an epoxy-free air gap between the optical fiber and ferrule near the fiber end face. Our high-power multimode fiber patch cables use connectors with this design feature.

Determining Power Handling with Multiple Damage Mechanisms

When fiber cables or components have multiple avenues for damage (e.g., fiber patch cables), the maximum power handling is always limited by the lowest damage threshold that is relevant to the fiber component. In general, this represents the highest input power that can be incident on the patch cable end face and not the coupled output power.

As an illustrative example, the graph to the right shows an estimate of the power handling limitations of a single mode fiber patch cable due to damage to the fiber end face and damage via an optical connector. The total input power handling of a terminated fiber at a given wavelength is limited by the lower of the two limitations at any given wavelength (indicated by the solid lines). A single mode fiber operating at around 488 nm is primarily limited by damage to the fiber end face (blue solid line), but fibers operating at 1550 nm are limited by damage to the optical connector (red solid line).

In the case of a multimode fiber, the effective mode area is defined by the core diameter, which is larger than the effective mode area for SM fiber. This results in a lower power density on the fiber end face and allows higher optical powers (on the order of kilowatts) to be coupled into the fiber without damage (not shown in graph). However, the damage limit of the ferrule / connector termination remains unchanged and as a result, the maximum power handling for a multimode fiber is limited by the ferrule and connector termination.

Please note that these are rough estimates of power levels where damage is very unlikely with proper handling and alignment procedures. It is worth noting that optical fibers are frequently used at power levels above those described here. However, these applications typically require expert users and testing at lower powers first to minimize risk of damage. Even still, optical fiber components should be considered a consumable lab supply if used at high power levels.

Intrinsic Damage Threshold

In addition to damage mechanisms at the air / glass interface, optical fibers also display power handling limitations due to damage mechanisms within the optical fiber itself. These limitations will affect all fiber components as they are intrinsic to the fiber itself. Two categories of damage within the fiber are damage from bend losses and damage from photodarkening.

Bend Losses

Bend losses occur when a fiber is bent to a point where light traveling in the core is incident on the core/cladding interface at an angle higher than the critical angle, making total internal reflection impossible. Under these circumstances, light escapes the fiber, often in a localized area. The light escaping the fiber typically has a high power density, which burns the fiber coating as well as any surrounding furcation tubing.

A special category of optical fiber, called double-clad fiber, can reduce the risk of bend-loss damage by allowing the fiber’s cladding (2nd layer) to also function as a waveguide in addition to the core. By making the critical angle of the cladding/coating interface higher than the critical angle of the core/clad interface, light that escapes the core is loosely confined within the cladding. It will then leak out over a distance of centimeters or meters instead of at one localized spot within the fiber, minimizing the risk of damage. Thorlabs manufactures and sells 0.22 NA double-clad multimode fiber, which boasts very high, megawatt range power handling.

Photodarkening

A second damage mechanism, called photodarkening or solarization, can occur in fibers used with ultraviolet or short-wavelength visible light, particularly those with germanium-doped cores. Fibers used at these wavelengths will experience increased attenuation over time. The mechanism that causes photodarkening is largely unknown, but several fiber designs have been developed to mitigate it. For example, fibers with a very low hydroxyl ion (OH) content have been found to resist photodarkening and using other dopants, such as fluorine, can also reduce photodarkening.

Even with the above strategies in place, all fibers eventually experience photodarkening when used with UV or short-wavelength light, and thus, fibers used at these wavelengths should be considered consumables.

Preparation and Handling of Optical Fibers

General Cleaning and Operation Guidelines

These general cleaning and operation guidelines are recommended for all fiber optic products. Users should still follow specific guidelines for an individual product as outlined in the support documentation or manual. Damage threshold calculations only apply when all appropriate cleaning and handling procedures are followed.

-

All light sources should be turned off prior to installing or integrating optical fibers (terminated or bare). This ensures that focused beams of light are not incident on fragile parts of the connector or fiber, which can possibly cause damage.

-

The power-handling capability of an optical fiber is directly linked to the quality of the fiber/connector end face. Always inspect the fiber end prior to connecting the fiber to an optical system. The fiber end face should be clean and clear of dirt and other contaminants that can cause scattering of coupled light. Bare fiber should be cleaved prior to use and users should inspect the fiber end to ensure a good quality cleave is achieved.

-

If an optical fiber is to be spliced into the optical system, users should first verify that the splice is of good quality at a low optical power prior to high-power use. Poor splice quality may increase light scattering at the splice interface, which can be a source of fiber damage.

-

Users should use low power when aligning the system and optimizing coupling; this minimizes exposure of other parts of the fiber (other than the core) to light. Damage from scattered light can occur if a high power beam is focused on the cladding, coating, or connector.

Tips for Using Fiber at Higher Optical Power

Optical fibers and fiber components should generally be operated within safe power level limits, but under ideal conditions (very good optical alignment and very clean optical end faces), the power handling of a fiber component may be increased. Users must verify the performance and stability of a fiber component within their system prior to increasing input or output power and follow all necessary safety and operation instructions. The tips below are useful suggestions when considering increasing optical power in an optical fiber or component.

-

Splicing a fiber component into a system using a fiber splicer can increase power handling as it minimizes possibility of air/fiber interface damage. Users should follow all appropriate guidelines to prepare and make a high-quality fiber splice. Poor splices can lead to scattering or regions of highly localized heat at the splice interface that can damage the fiber.

-

After connecting the fiber or component, the system should be tested and aligned using a light source at low power. The system power can be ramped up slowly to the desired output power while periodically verifying all components are properly aligned and that coupling efficiency is not changing with respect to optical launch power.

-

Bend losses that result from sharply bending a fiber can cause light to leak from the fiber in the stressed area. When operating at high power, the localized heating that can occur when a large amount of light escapes a small localized area (the stressed region) can damage the fiber. Avoid disturbing or accidently bending fibers during operation to minimize bend losses.

-

Users should always choose the appropriate optical fiber for a given application. For example, large-mode-area fibers are a good alternative to standard single mode fibers in high-power applications as they provide good beam quality with a larger MFD, decreasing the power density on the air/fiber interface.

-

Step-index silica single mode fibers are normally not used for ultraviolet light or high-peak-power pulsed applications due to the high spatial power densities associated with these applications.

| Posted Comments: | |

Arivazhagan Arivu

(posted 2023-02-02 16:15:10.467) Regarding photosensitive single mode fiber GF1, here its mentioned that "doped silica core". what is the material is doped here? jgreschler

(posted 2023-02-02 04:03:50.0) Thank you for reaching out to Thorlabs. For GF1, the core is silica doped with both Germanium and Boron. For additional data or specifications please contact techsupport@thorlabs.com PETER LEE

(posted 2022-11-23 14:18:24.473) what is dispersion at wavelength 1030 nm?

Is there dispersion curve(v.s wavelength) of this fiber?

any information of dispersion is helpful!thanks! jgreschler

(posted 2022-11-23 11:08:13.0) Thank you for reaching out to Thorlabs. Additional data and specs can be requested by contacting techsupport@thorlabs.com. In this case we unfortunately don't have the data at 1030nm since that is outside the operating range of GF1. PETER LEE

(posted 2022-11-23 14:17:24.98) what is dispersion at wavelength 1030 nm?

Is there dispersion curve(v.s wavelength) of this fiber?

any information of dispersion is helpful!thanks! jgreschler

(posted 2022-11-23 11:08:14.0) Thank you for reaching out to Thorlabs. Additional data and specs can be requested by contacting techsupport@thorlabs.com. In this case we unfortunately don't have the data at 1030nm since that is outside the operating range of GF1B. aldergazly

(posted 2013-12-27 01:47:59.9) we need fiber Bragg grating in the range 400-700nm pbui

(posted 2014-01-02 04:05:47.0) Response from Phong at Thorlabs: Thank you for your interest. We offer a variety of fibers that are specifically designed for use in writing fiber Bragg gratings, but we do not yet carry one with a 400-700 nm design wavelength in our catalog. We will contact you directly to discuss your requirements and to see if we can offer a suitable fiber solution. vtgopakumar111

(posted 2013-02-16 03:58:19.787) Sir/Madam

What is the Neff(Effective refractive index) of the fiber @ 1550nm or the entire C band

Thanks

VT Gopakumar cdaly

(posted 2013-02-20 19:59:00.0) Response from Chris at Thorlabs: Thank you for your feedback. The effective index of the GF1 fiber is 1.469 at 1310 nm and 1.470 at 1550 nm. jlow

(posted 2012-11-08 14:07:00.0) Response from Jeremy at Thorlabs: We do not have data for the attenuation for the GF1. As an estimate, it would be on the order of tens of dB/km at 1550nm. The attenuation is relatively large because of the heavy doping but the typical length used is a few meters so the attenuation is not a big concern. soonlink

(posted 2012-11-01 05:58:36.187) Could you give me the data of the attenuation @1550 nm ( dB/Km ) for this kind of photosensitive fiber ? |

- Enhanced Photosensitivity

- Low Splice Loss to Transmission Fibers

These general purpose photosensitive fibers are highly sensitive to UV radiation and are modematched to SMF-28e. These fibers are designed to reduce FBG writing times associated with industry standard telecommunication fiber and can be easily spliced to industry standard fiber as well.

We recommend T06S13 for use as a stripper tool when removing the buffer from these optical fibers in preparation for connectorization.

| Item # | Operating Wavelength |

MFD @ 1310 nm | MFD @ 1550 nm | Cladding | Coating | Cut-Off Wavelength |

NA | Core Index |

Cladding Index |

Proof Test |

|---|---|---|---|---|---|---|---|---|---|---|

| GF1 | 1500 - 1600 nm | 9.3 ± 0.5 µm | 10.5 ± 1.0 µm | 125 ± 1.5 µm | 250 ± 20 µm | 1260 ± 75 nm | 0.13 | Calla | Calla | ≥100 kpsi |

| GF3 | 1500 - 1600 nm | - | 7.5 ± 0.5 µm | 125 ± 1.0 µm | 245 ± 15 µm | 1350 ± 50 nm | 0.16 | Calla | Calla | ≥100 kpsi |

- Low Background Attenuation

- Splice Compatible with SMF-28e

- UV Photosensitive

The low-loss photosensitive fiber provides much higher photosensitivity than standard transmission fibers to UV radiation. This fiber is specifically designed to be splice compatible with SMF-28e and may be used in WDM applications. The reduced attenuation allows the fiber to be used in longer lengths and reduces the insertion loss in manufactured fiber optic components.

We recommend T06S13 for use as a stripper tool when removing the buffer from these optical fibers in preparation for connectorization.

| Item # | Operating Wavelength | MFD @ 1550 nm | Cladding | Coating | Cut-Off Wavelength |

NA | Core Index | Cladding Index | Proof Test |

|---|---|---|---|---|---|---|---|---|---|

| GF1B | 1500 - 1600 nm | 10.4 ± 0.8 µm | 125 ± 1.0 µm | 245 ± 15 µm | 1260 ± 100 nm | 0.13 | Calla | Calla | ≥100 kpsi |

- High Photosensitivity

- High Cladding Mode Offset: 9 nm (Typical)

- Tight Tolerances

The Cladding Mode Offset Fiber is designed specifically with improved cladding mode offset. The cladding mode offset operation enhances the fiber's performance when writing two or more gratings adjacent to each other (9 nm offset typical). Cladding Mode Offset fibers exhibit low splice loss to the industry standard telecommunications fiber.

We recommend T06S13 for use as a stripper tool when removing the buffer from these optical fibers in preparation for connectorization.

| Item # | Operating Wavelength | MFD @ 1550 nm | Cladding | Coating | Cut-Off Wavelength |

NA | Core Index | Cladding Index | Proof Test |

|---|---|---|---|---|---|---|---|---|---|

| GF4A | 1500 - 1600 nm | 4.0 ± 0.3 µm | 125 ± 1.5 µm | 250 ± 20 µm | 1350 ± 100 nm | 0.30 | Calla | Calla | ≥100 kpsi |

- High Photosensitivity

- Low Splice Loss to Transmission Fiber

- Low Cost, High Yield Grating Fabrication

The PS1060 photosensitive fiber is designed to provide high photosensitivity to UV radiation. This fiber is specifically designed for use in writing fiber Bragg gratings for pump stabilizers or diode output wavelengths in the 980 to 1060 nm range. PS1060 may also be used in coupler applications.

We recommend T06S13 for use as a stripper tool when removing the buffer from these optical fibers in preparation for connectorization.

| Item # | Operating Wavelength | MFD @ 1060 nm | Cladding | Coating | Cut-Off Wavelength |

NA | Core Index | Cladding Index | Proof Test |

|---|---|---|---|---|---|---|---|---|---|

| PS1060 | 980 - 1060 nm | 6.2 ± 0.8 µm | 125 ± 1.5 µm | 245 ± 15 µm | 920 ± 50 nm | 0.13 | Calla | Calla | ≥100 kpsi |

- Low Attenuation

- All PM Attributes with Enhanced Photosensitivity

- High Lot-to-Lot Uniformity

Designed for use in 980 nm pump lasers diodes, couplers and multiplexers, PS-PM980 offers enhanced photosensitivity that substantially reduces writing times as well as excellent polarization maintaining attributes.

We recommend T06S13 for use as a stripper tool when removing the buffer from these optical fibers in preparation for connectorization.

| Item # | Operating Wavelength | MFD @ 980 nm | Cladding | Coating | Cut-Off Wavelength |

NA | Core Index | Cladding Index | Proof Test |

|---|---|---|---|---|---|---|---|---|---|

| PS-PM980 | 970 - 1550 nm | 6.6 ± 1.0 µm | 125 ± 1.0 µm | 245 ± 15 µm | 900 ± 70 nm | 0.12 | Calla | Calla | ≥100 kpsi |

Products Home

Products Home

Single Mode

Single Mode